Tips for Choosing the Right Size Copper Pipes for Plumbing

Tips for Selecting the Correct Size of Copper Pipes for Plumbing Projects

Selecting the correct size of copper pipes is crucial for plumbing projects to ensure optimal water flow and pressure. In this comprehensive guide, readers will learn the importance of accurate measurements in plumbing and how to avoid common issues caused by incorrect pipe sizing. Understanding the impact of pipe diameter on water quality, maintenance needs, and overall costs is essential for successful plumbing projects.

Tools and Materials Needed

Essential Tools

Measuring Tape

For accurate measurements in plumbing projects, a measuring tape is an indispensable tool. It allows precise determination of the required length for copper pipes, ensuring a perfect fit every time.

Pipe Caliper

When it comes to measuring the diameter of copper pipes, a pipe caliper is essential. This tool provides accurate readings, allowing for the selection of the right pipe size based on specific project requirements.

Pipe Cutter

To ensure clean and precise cuts on copper pipes, a pipe cutter is necessary. It simplifies the cutting process, resulting in smooth edges that facilitate seamless connections.

Required Materials

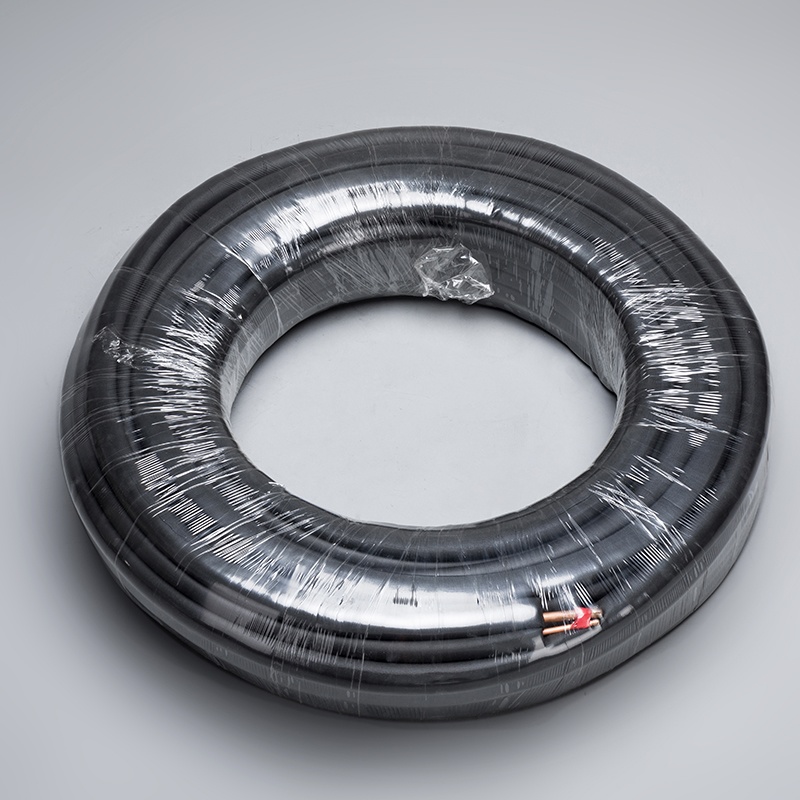

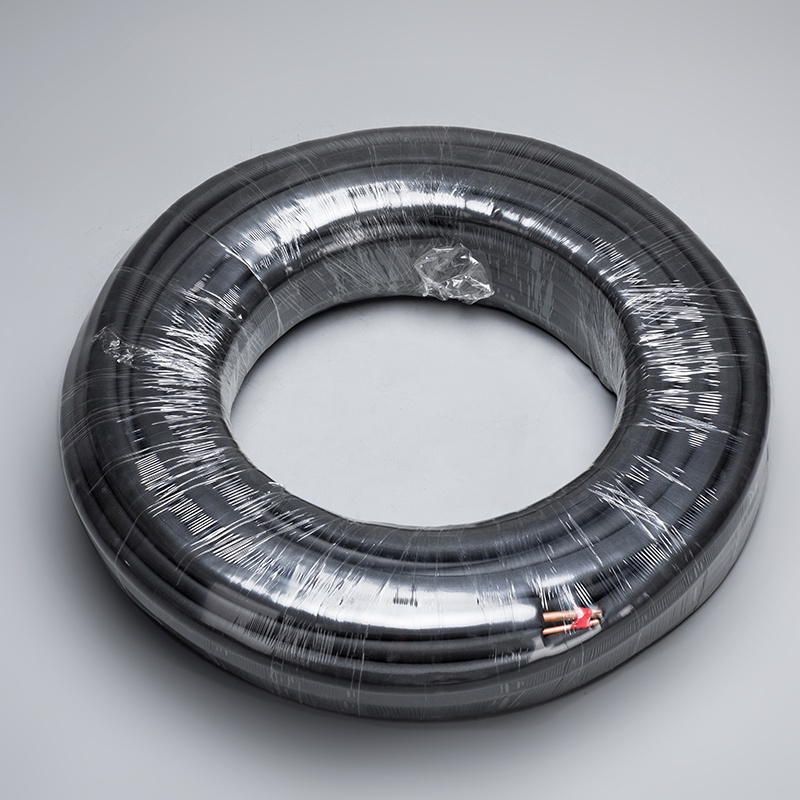

Different Types of Copper Pipes

Choosing the appropriate type of copper pipes is crucial for the success of any plumbing project. Whether it's rigid copper pipes for water supply or flexible copper tubing for intricate installations, selecting the right material is key.

Pipe Insulation

In colder climates, pipe insulation plays a vital role in preventing freezing and maintaining optimal water temperature. By insulating copper pipes, you can enhance energy efficiency and protect against potential damage.

Fittings and Connectors

Selecting high-quality fittings and connectors ensures secure joints between copper pipes, preventing leaks and enhancing overall system durability. Properly matched fittings guarantee a reliable plumbing setup.

Steps for Measuring Copper Pipe Size

Understanding Pipe Sizing Standards

Nominal Pipe Size (NPS)

When determining the Nominal Pipe Size (NPS) of copper pipes, it is essential to consider the standardized sizing system that simplifies identification. Each NPS corresponds to a specific outer diameter, facilitating accurate selection based on project requirements.

Outside Diameter (OD)

The Outside Diameter (OD) of copper pipes plays a crucial role in determining compatibility with fittings and connectors. By measuring the outer circumference of the pipe, you can ensure precise connections and efficient water flow throughout the plumbing system.

Measuring the Pipe

Using a Measuring Tape

Utilizing a measuring tape simplifies the process of measuring copper pipes accurately. By wrapping the tape around the pipe's circumference, you can determine its size with precision, ensuring compatibility with fittings and connectors.

Using a Pipe Caliper

A pipe caliper provides precise readings of the diameter of copper pipes, allowing for informed decisions on selecting the right size. By measuring both inner and outer diameters, you can ensure optimal fit and functionality within your plumbing setup.

Recording Measurements

Importance of Accuracy

Maintaining accuracy in recording measurements is paramount when selecting copper pipes for plumbing projects. Precision ensures proper fitting, preventing leaks and inefficiencies that may arise from incorrect pipe sizing.

Common Mistakes to Avoid

Avoiding errors such as inaccurate measurements or misinterpretation of sizing standards is crucial in successful plumbing projects. By double-checking measurements and adhering to industry standards, you can mitigate potential issues and ensure seamless installations.

Preparing the Copper Pipe

Cutting the Pipe

Mastering copper cutting in plumbing is a fundamental skill that every plumber should strive to achieve. With the knowledge, techniques, and tools provided in this article, you’ll be well on your way to becoming a copper cutting expert, capable of creating precise cuts for secure connections and leak-free plumbing systems. So, let’s dive in and explore the world of copper cutting in plumbing.

Using a Pipe Cutter

Start by selecting the appropriate pipe cutter based on the size of the copper pipe you are working with.

Position the cutter perpendicular to the pipe and rotate it around the pipe's circumference.

Apply consistent pressure while rotating the cutter to ensure a clean and even cut without deforming the pipe.

Ensuring a Clean Cut

After cutting the copper pipe, remove any burrs or rough edges using a deburring tool.

Smooth out any imperfections on the cut end to facilitate easy fitting and prevent disruptions in water flow.

Inspect the cut end visually and by touch to confirm its smoothness before proceeding with installation.

Deburring the Pipe

Prepwork is critical to ensuring a good soldered joint, and cleaning of the copper is the first step. I've used several tools and methods for cleaning both the pipe and fitting.

Tools for Deburring

Utilize a deburring tool specifically designed for copper pipes to remove any sharp edges or burrs.

Ensure that all debris from cutting is eliminated to prevent obstructions during assembly.

Regularly check and maintain your deburring tool for optimal performance when working on multiple cuts.

Techniques for Smooth Edges

Rotate the deburring tool around the inner edge of the copper pipe to eliminate any irregularities.

Apply gentle pressure while deburring to avoid damaging or distorting the pipe's surface.

Verify that both ends of the copper pipe are smoothly deburred before proceeding with fittings.

Fitting and Connecting

Choosing high-quality fittings ensures secure joints between copper pipes, preventing leaks and enhancing overall system durability. Properly matched fittings guarantee a reliable plumbing setup.

Choosing The Right Fittings

Select fittings that match both your copper pipe size and type for compatibility.

Consider factors such as material quality, threading precision, and sealing capabilities when choosing fittings.

Opt for reputable brands known for producing durable fittings that meet industry standards.

Ensuring A Secure Connection

Clean both ends of your copper pipes thoroughly before connecting them with fittings.

Apply flux evenly on each mating surface to promote proper solder adhesion during assembly.

Heat each joint uniformly using a torch until solder flows smoothly into all connection points.

Importance of Accurate Measurements

Avoiding Common Plumbing Issues

Leaks and Water Damage: When copper pipes are not accurately sized for a plumbing project, the risk of leaks and water damage increases. Incorrectly sized pipes may struggle to handle the water flow, leading to potential leaks that can result in costly repairs and property damage.

Inefficient Water Flow: Inadequate pipe sizing can also cause inefficient water flow within a plumbing system. If the pipes are too small, water pressure may be compromised, affecting the overall performance of fixtures and appliances. Properly sized copper pipes ensure optimal water flow throughout the system.

Ensuring System Longevity

Preventing Wear and Tear: By selecting the correct size of copper pipes, you can prevent unnecessary wear and tear on your plumbing system. Pipes that are too small may experience increased stress due to high water pressure, leading to premature deterioration. Choosing the right size promotes longevity and reduces maintenance needs.

Maintaining Optimal Performance: Properly sized copper pipes contribute to maintaining optimal performance in your plumbing setup. When each component is accurately measured and fitted, the entire system functions efficiently without disruptions. This ensures that water flows smoothly, fixtures operate effectively, and the overall system performs at its best.

Recap: Choosing the correct size of copper pipes is vital for plumbing projects to ensure optimal water flow and pressure. Accurate measurements lead to improved water quality, cost savings, and lower maintenance needs.

Summary: The tools discussed, like measuring tape and pipe cutter, are essential for precise pipe sizing. Steps such as understanding NPS and OD help in selecting the right copper pipes. Proper preparation with clean cuts and secure fittings ensures a successful plumbing setup.

Final Tips: Double-check measurements, consult professionals when needed, and prioritize accurate sizing for efficient plumbing systems.

Encouragement: Follow this guide diligently for accurate measurements and seamless plumbing projects.

See Also

Selecting the Correct Copper Pipe Diameter: 5 Key Steps

The Ultimate Handbook: Measuring Copper Pipe Dimensions

Mastering Unconventional 1/2' Copper Pipe Handling: 5 Tips