Troubleshooting Compression Fittings on Copper Pipes

Guides to troubleshooting compression fittings on copper pipes are essential for maintaining a reliable plumbing system. Compression fittings play a crucial role in ensuring secure connections for copper pipes. However, issues with these fittings can lead to leaks and inefficiencies. This blog aims to equip you with a comprehensive Guides to address common compression fitting challenges effectively. By understanding the intricacies of compression fittings and mastering troubleshooting techniques, you can maintain the integrity of your plumbing system effortlessly.

Understanding Compression Fittings

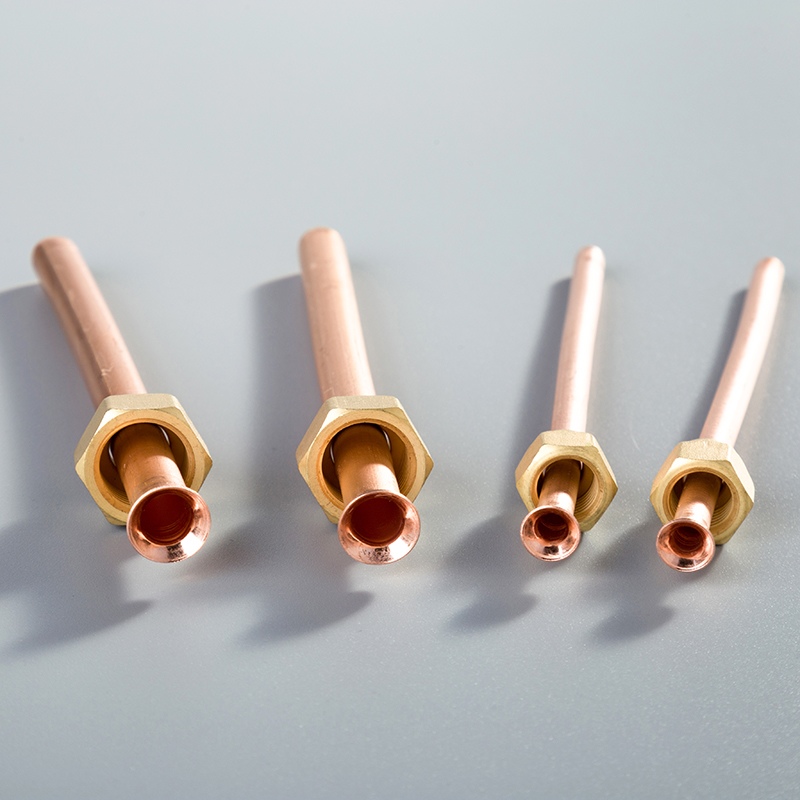

Compression Fittings: A vital component in plumbing systems, compression fittings ensure secure connections for copper pipes. These fittings consist of two main parts: the coupling nut and the compression ring. Widely used across industries, compression fittings offer exceptional temperature and pressure capabilities, making them ideal for various applications.

What are Compression Fittings?

Components of Compression Fittings

The coupling nut and the compression ring are the key components of compression fittings.

The coupling nut secures the connection by compressing the compression ring onto the pipe.

How Compression Fittings Work

When the coupling nut is tightened, it compresses the compression ring, creating a tight seal around the pipe.

This mechanism ensures a leak-free connection between pipes or tubing.

Types of Compression Fittings

Standard Compression Fittings

Standard compression fittings are versatile and commonly used in plumbing systems.

They provide a reliable method to connect copper pipes securely without soldering.

Flare Compression Fittings

Flare compression fittings are specialized fittings that create a tight seal through flaring.

These fittings are often used in situations where a higher level of sealing is required.

Common Issues with Compression Fittings on Copper Pipes

Leaks

Causes of Leaks

High pressure levels on compression fittings can lead to leaks, especially if the connection involves a pipe or fitting at an angle. This situation may potentially distort the o-ring, compromising the seal integrity.

Inspecting compression fittings and ferrules for any damage or imperfections is crucial. Even minor flaws can result in leaks that affect the overall performance of the plumbing system.

Identifying Leak Points

When troubleshooting leaks in compression fittings, it's essential to check for movable tubing after tightening the compression nut. Any movement indicates a potential issue with the fitting that requires immediate attention.

If a joint leaks after compression fitting, consider loosening and retightening the compression nut to ensure a proper seal. This simple step can often resolve minor leak issues effectively.

Loose Connections

Causes of Loose Connections

Over time, corrosion can contribute to loose connections in compression fittings on copper pipes. Regular maintenance and inspection are key to preventing this common issue.

Pre-swaging the ferrule onto the pipe before adding sealant can help improve the connection's stability and reduce instances of loose fittings.

How to Tighten Connections Properly

Begin by ensuring that all components are clean and free from debris.

Use an appropriate wrench to tighten the compression nut securely onto the fitting.

Follow the manufacturer's instructions for tightening recommendations based on your specific compression fitting type.

Corrosion

Causes of Corrosion

Corrosion is often caused by exposure to moisture or chemicals present in the environment where copper pipes are installed. These factors can weaken the integrity of compression fittings over time.

Inspecting and cleaning corroded areas regularly can help identify early signs of corrosion and prevent further damage to your plumbing system.

Preventing Corrosion

Applying anti-corrosion products on compression fittings can provide an additional layer of protection against environmental factors that contribute to corrosion.

Regular maintenance, including checking for signs of corrosion and addressing them promptly, is essential for prolonging the lifespan of your copper pipes and compression fittings.

Step-by-Step Troubleshooting Guide

Tools and Materials Needed

Essential Tools

Pipe cutter

Adjustable wrench

Tubing cutter

Deburring tool

Recommended Materials

Replacement ferrules

Thread sealant tape

Anti-corrosion spray

Inspecting the Fitting

Visual Inspection

To begin troubleshooting, visually inspect the compression fitting for any signs of damage or irregularities. Look for dents, cracks, or corrosion on both the coupling nut and compression ring.

Checking for Wear and Tear

Examine the tubing connected to the fitting for wear and tear. Ensure there are no visible signs of deformation or kinks that could affect the sealing capability of the compression fitting.

Fixing Leaks

Tightening the Fitting

When addressing leaks in compression fittings, start by gently tightening the coupling nut with an appropriate wrench. Avoid over-tightening, as this can damage the components and lead to further leaks.

Replacing the Ferrule

If tightening the fitting does not resolve the leak issue, consider replacing the ferrule. Carefully remove the old ferrule using a pipe cutter or specialized tool before installing a new one securely onto the tubing.

Addressing Loose Connections

Proper Tightening Techniques

To ensure secure connections and prevent leaks in compression fittings on copper pipes, it is essential to employ proper tightening techniques. By following these guidelines, you can maintain the integrity of your plumbing system effectively:

Inspect the Fitting: Before tightening the compression nut, visually inspect the fitting for any signs of damage or wear. Ensure that both the coupling nut and compression ring are in good condition.

Use an Appropriate Wrench: Select a suitable wrench that fits the compression nut securely. Avoid using tools that may cause damage to the components or lead to over-tightening.

Apply Even Pressure: When tightening the compression nut, apply even pressure to create a uniform seal around the pipe. Avoid excessive force that could deform the ring or tubing.

Using Thread Sealant

In addition to proper tightening techniques, using thread sealant can further enhance the connection's stability and prevent potential leaks. Follow these steps to effectively apply thread sealant:

Clean the Threads: Before applying sealant, ensure that the threads on both the compression fitting and pipe are clean and free from debris.

Apply Sealant Sparingly: Use a small amount of thread sealant on the male threads of the fitting. Avoid excess sealant that could interfere with the connection.

Tighten Securely: After applying sealant, tighten the compression nut according to manufacturer recommendations. The combination of proper tightening and sealant application can significantly reduce the risk of leaks.

By implementing these techniques, you can address loose connections in compression fittings on copper pipes proactively and maintain a reliable plumbing system for your home or business.

Summarize the key points discussed in the blog, highlighting common issues like leaks, loose connections, and corrosion.

Emphasize the significance of regular maintenance to prevent potential problems with compression fittings on copper pipes.

Recommend seeking professional assistance for complex issues or installations requiring expert knowledge.

Conclude by underlining the benefits of well-maintained compression fittings, ensuring a reliable and efficient plumbing system.

See Also

Simple Guide: Attaching Compression Fittings to Bent Copper Pipes

Quick Fixes for Copper Pipe Coil Issues

Key Pointers for Utilizing 1/4 Copper Pipe Fittings