Understanding Different Types of Copper Pipe Connections

Understanding the intricacies of types of copper pipe connections is crucial for any plumbing project. With various methods available, from soldering to compression fittings, choosing the right connection ensures a leak-free and efficient system. This blog provides a concise overview of these connection types, highlighting their applications and benefits. By delving into the nuances of the best way to connect copper pipe and brass to copper pipe connection, readers will gain valuable insights for their plumbing endeavors.

Types of Copper Pipe Connections

When it comes to types of copper pipe connections, there are several methods available, each with its unique advantages and applications. Understanding these connection techniques is essential for any plumbing project to ensure a reliable and efficient system.

Solder or Brazed Joints

Soldering is a common method used to join copper pipes together. It involves melting a filler material, known as solder, into the joint to create a secure connection.

The brazing process is similar to soldering but requires higher temperatures. It is often preferred for larger pipes due to its strength and durability.

No-flame Joints

Push-fit Connections

Push-fit connections offer a convenient way to connect copper pipes without the need for soldering or specialized tools. These fittings feature a simple push-to-connect design for quick installation.

Press-fit Connections are becoming increasingly popular for smaller diameter piping. They provide a reliable and leak-proof joint by using a press tool to secure the fitting onto the pipe.

Additional Joining Methods

Compression Fittings

Compression fittings provide a reliable and straightforward way to join copper pipes without welding or soldering. These fittings use compression rings to create a tight seal between the pipe and fitting.

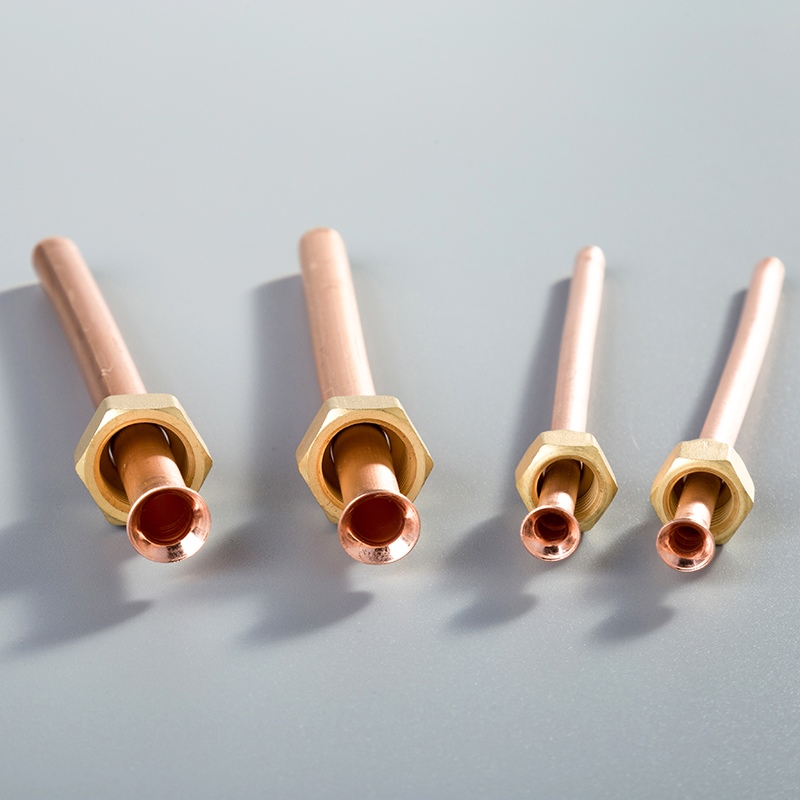

Flare Fittings are commonly used when connecting copper tubing to fixtures or appliances. They involve flaring the end of the pipe and using a flare nut to secure it in place.

In plumbing projects, choosing the right types of copper pipe connections is crucial for ensuring long-term performance and preventing leaks. Whether opting for traditional soldered joints or modern push-fit fittings, each method offers distinct benefits based on the specific requirements of the installation.

Best Way to Connect Copper Pipe

When considering the best way to connect copper pipe, several factors come into play to ensure a successful plumbing project. Evaluating the durability and ease of installation of different connection methods is crucial for achieving a reliable and efficient system.

Factors to Consider

Durability

Opting for a connection method with high durability is essential to prevent future leaks and maintain the integrity of the plumbing system. Copper press fittings stand out for their rapid installation time and long-lasting performance. These fittings offer a secure joint that can withstand various pressures, ensuring a leak-free system for years to come.

On the other hand, traditional soldered connections provide unmatched reliability, especially in high-temperature or high-vibration systems. The manual application of solder ensures a strong bond between copper pipes, offering long-term peace of mind for homeowners and professionals alike.

Ease of Installation

When it comes to ease of installation, pre-soldered fittings offer a convenient solution for quick and efficient plumbing projects. These fittings eliminate the need for manual solder application, saving time and effort during installation. Their user-friendly design simplifies the connection process, making them an ideal choice for both DIY enthusiasts and experienced plumbers.

In contrast, traditional soldering methods require precision and skill to create secure joints between copper pipes. While this method may take longer than using pre-soldered fittings, it offers unparalleled strength and reliability in demanding environments.

Comparison of Methods

Soldering vs. Push-fit

The debate between soldering and push-fit connections often centers around speed versus reliability. While soldering provides a permanent connection that can withstand extreme conditions, push-fit fittings offer quick and tool-free installations for simple plumbing tasks. Homeowners looking for convenience may opt for push-fit connections, while professionals prioritize the durability of soldered joints in critical applications.

Compression vs. Press-fit

Choosing between compression and press-fit connections involves weighing simplicity against efficiency. Compression fittings provide a straightforward method for joining copper pipes without welding or soldering, making them suitable for various installations. On the other hand, press-fit connections offer rapid installation times and durable seals that ensure long-term performance in residential and commercial settings.

Brass to Copper Pipe Connection

Connecting brass to copper pipe is a critical aspect of plumbing projects that requires precision and the right techniques to ensure a reliable and durable joint.

Importance of Proper Connection

To prevent corrosion in the long run, it is essential to establish a secure connection between brass and copper pipes. This not only safeguards the integrity of the plumbing system but also prolongs its lifespan, minimizing the risk of leaks or damage.

Preventing Corrosion

Corrosion can weaken the connection between brass and copper pipes over time, leading to potential leaks or system failures. By using appropriate fittings and techniques, such as compression fittings or flare fittings, you can mitigate the risk of corrosion and maintain a robust connection for years to come.

Ensuring Leak-proof Joints

Ensuring leak-proof joints when connecting brass to copper pipes is paramount for maintaining the efficiency and functionality of the plumbing system. Properly sealed connections prevent water leakage, preserving water pressure and preventing costly repairs down the line.

Methods for Connecting Brass to Copper

When it comes to connecting brass to copper pipes, there are two primary methods that are commonly used: compression fittings and flare fittings. Each method offers unique advantages based on the specific requirements of the installation.

Using Compression Fittings

Compression fittings provide a reliable way to connect brass to copper pipes without requiring soldering or welding. These fittings feature a compression ring that creates a tight seal between the pipes, ensuring a leak-free joint. The simplicity and effectiveness of compression fittings make them ideal for various plumbing applications where ease of installation is key.

Using Flare Fittings

Flare fittings are another popular choice for connecting brass to copper pipes, especially in applications where a secure and leak-proof joint is essential. By flaring the end of the copper pipe and using a flare nut to secure it in place, flare fittings create a strong connection that can withstand high pressures. This method is often preferred for connecting tubing to fixtures or appliances due to its durability and reliability.

Selecting the appropriate copper pipe fitting confidently ensures a safe, efficient, cost-effective piping system.

Consider the application, size of the fitting, operating conditions, requirements of the job, and your skill set when selecting copper fittings for your project.

Choosing the right copper fittings is crucial for a successful and reliable plumbing system.

Key factors to consider when selecting the right fittings for your project can lead to faster completion of plumbing projects and reduce the risk of future problems.

The choice between compression fittings and soldering depends on specific needs, skill level, and working conditions.

See Also

Exploring Different Copper Pipe Varieties and Soldering Techniques

Decoding Copper Pipe Dimensions: An In-Depth Manual

Top 5 Recommendations for 1/4 Copper Pipe Connectors

Revealing the Development of 1 2 Copper Tubing in Building

Becoming Proficient in Copper Pipe Connectors: An Extensive Manual