Understanding the Types of Copper Pipes and Tubing

Copper pipes and tubings play a vital role in modern systems, offering unmatched durability and efficiency. Their resistance to corrosion ensures long-lasting performance, making them a reliable choice for water distribution, HVAC, and industrial applications. Unlike other materials, copper maintains water purity and withstands extreme conditions without degrading. Its excellent thermal and electrical conductivity further enhances its versatility. Whether for residential plumbing or large-scale industrial use, copper pipes and tubings provide a dependable solution that balances strength, longevity, and safety.

Key Takeaways

Copper pipes and tubing are highly durable and can last up to 50-60 years with proper maintenance, making them a cost-effective choice for plumbing and HVAC systems.

Different types of copper pipes (Type K, L, M, and DWV) serve specific applications; understanding their characteristics helps you select the right one for your project.

Type K pipes are ideal for high-pressure environments, while Type L is commonly used for residential plumbing, and Type M offers a budget-friendly option for low-pressure systems.

Flexible copper tubing is perfect for applications requiring bends and curves, such as refrigeration and gas lines, while rigid tubing is best for stable, high-pressure systems.

Regular maintenance, including monitoring water quality and inspecting for leaks, is crucial to prevent corrosion and extend the lifespan of copper pipes.

Choosing the right type of copper pipe or tubing based on application, durability needs, and budget ensures optimal performance and safety in your plumbing systems.

Overview of Copper Pipes and Tubing

Copper pipes and tubing are essential components in various systems, offering unmatched reliability and performance.

What Are Copper Pipes and Tubing?

Copper pipes and tubing are cylindrical materials made from high-quality copper or copper alloys. They serve as conduits for transporting water, gas, and other fluids in residential, commercial, and industrial systems. Unlike other materials, copper resists corrosion and maintains its structural integrity over time. This makes it a dependable option for environments where durability and safety are critical.

You’ll find copper piping in water distribution networks, heating systems, and refrigeration lines. Its versatility allows it to adapt to various applications, whether for rigid installations or flexible setups. Copper tubing, in particular, is available in two forms: rigid and flexible. Each type caters to specific needs, ensuring optimal performance in different scenarios.

Key Benefits of Copper Pipes and Tubing

Durability and Longevity

With proper maintenance, they can last up to 50 or 60 years, making them a cost-effective investment.

Corrosion Resistance

One of the standout features of copper is its natural resistance to corrosion. Unlike materials that rust or degrade over time, copper maintains its integrity when exposed to moisture, chemicals, or harsh conditions. This property not only extends the lifespan of copper piping but also ensures the purity of the fluids it transports. You can trust copper to deliver clean water without contamination.

Thermal and Electrical Conductivity

Copper’s excellent thermal and electrical conductivity sets it apart from other materials. It efficiently transfers heat, making it ideal for HVAC systems and radiant heating applications. Its ability to conduct electricity also makes it a reliable choice for electrical wiring and grounding systems. These properties enhance its versatility and make it indispensable in modern infrastructure.

Types of Copper Piping

Copper piping comes in several varieties, each designed to meet specific needs. Understanding the differences between these types of copper helps you select the best option for your project.

Type K Copper Piping

Characteristics and Applications

Type K copper piping is the most durable option available. Its thick walls make it ideal for high-pressure environments. You can rely on this type of pipe for underground water lines, main water supply systems, and fire protection networks. It also performs well in HVAC applications, where strength and reliability are critical.

If you need a pipe that can handle extreme pressure or environmental challenges, Type K is the best choice.

Type L Copper Piping

Characteristics and Applications

Type L copper piping is the most commonly used option for residential plumbing. It features slightly thinner walls than Type K but still offers excellent durability. This type of pipe works well for both hot and cold water systems. It is also suitable for HVAC systems, where moderate pressure levels are present.

You will find Type L pipes in homes, commercial buildings, and institutional settings. They are versatile and reliable, making them a popular choice for interior plumbing. Their ability to withstand pressure ensures consistent performance over time. If you are working on a residential plumbing project, Type L pipes provide a dependable solution.

Type M Copper Piping

Characteristics and Applications

Type M copper piping is the most affordable option among the three. Its thinner walls make it lighter and easier to work with. This type of pipe is commonly used in residential plumbing systems, especially for heating applications. It is suitable for low-pressure environments where cost-effectiveness is a priority.

You will often see Type M pipes in homes where budget constraints exist. Despite its thinner walls, this type of pipe still offers good durability for standard plumbing needs. If you are looking for an economical solution for residential plumbing, Type M pipes are a practical choice.

DWV Copper Piping

DWV copper piping, short for Drain, Waste, and Vent piping, serves a specialized role in plumbing systems. Unlike other types of copper piping, DWV pipes are not designed to handle pressurized water. Instead, they excel in managing the flow of non-pressurized waste and venting gases out of your plumbing system. Their unique characteristics make them indispensable for maintaining proper drainage and ventilation in residential, commercial, and industrial settings.

Characteristics and Applications

DWV copper piping features thinner walls compared to other types of copper piping, such as Type K or Type L. This design reduces material costs and makes the pipes lightweight, which simplifies installation. However, the thinner walls mean DWV pipes are unsuitable for carrying pressurized water. You will find these pipes primarily in systems where gravity facilitates the movement of fluids and gases.

The primary applications of DWV copper piping include:

Drainage Systems: DWV pipes efficiently transport wastewater from sinks, showers, and toilets to the main sewer line. Their corrosion resistance ensures long-term reliability, even when exposed to harsh substances.

Waste Systems: These pipes handle the safe disposal of liquid and solid waste, preventing blockages and leaks that could compromise your plumbing system.

Vent Systems: Proper ventilation is crucial for maintaining air pressure within your plumbing system. DWV pipes allow harmful gases, such as methane, to escape safely through vent stacks, ensuring a healthy and odor-free environment.

DWV copper piping stands out for its durability and resistance to corrosion. Unlike plastic alternatives, copper does not degrade over time or release harmful chemicals into the environment. This makes it a sustainable and eco-friendly choice for drainage, waste, and vent systems.

When selecting DWV copper piping, consider the specific requirements of your project. If you need a reliable solution for non-pressurized applications, DWV pipes offer an excellent balance of performance and cost-effectiveness. Their ability to withstand exposure to moisture and chemicals ensures they remain functional for decades, providing peace of mind and long-term value.

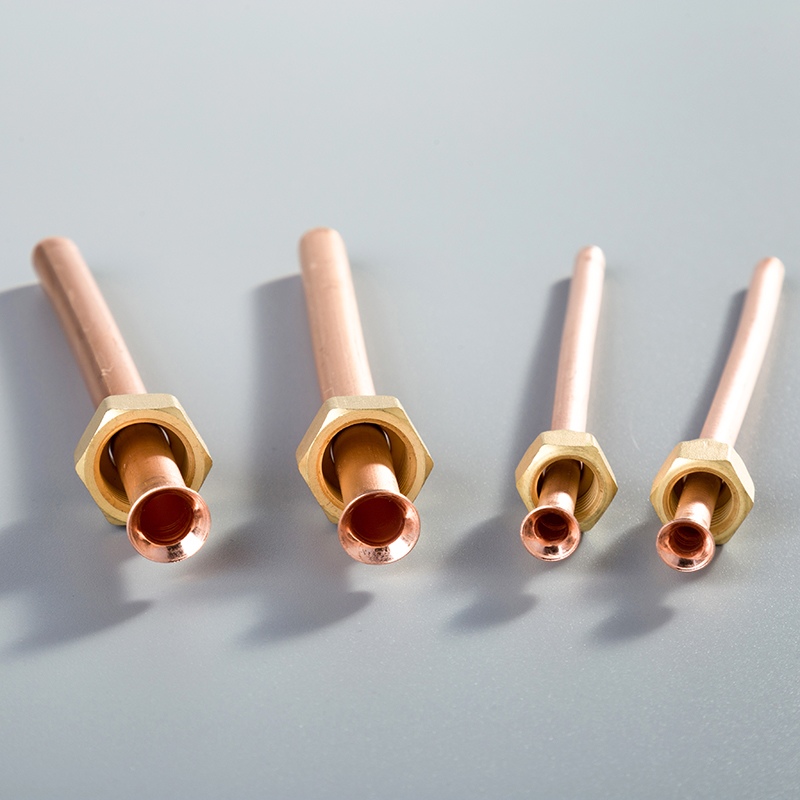

Types of Copper Tubing

Copper tubing plays a vital role in various systems, offering flexibility and durability for different applications. Understanding the two main types—flexible and rigid—helps you choose the right option for your needs.

Flexible Copper Tubing

Characteristics and Applications

Flexible copper tubing is designed to adapt to installations requiring bends and curves.

Flexible copper tubing is commonly used in refrigeration systems and gas lines. Its ability to handle low-pressure applications makes it ideal for these purposes. For refrigeration, it efficiently transports refrigerants, ensuring optimal cooling performance. In gas lines, it provides a safe and reliable conduit for natural gas or propane.

This tubing type also resists corrosion, ensuring long-term reliability. Its lightweight nature simplifies installation, saving time and effort. If your project involves intricate pathways or requires a material that can withstand bending, flexible copper tubing offers an excellent solution.

Rigid Copper Tubing

Characteristics and Applications

Rigid copper tubing, also known as rigid copper pipe, is the go-to choice for water supply systems.

You will often find rigid copper tubing in water supply lines for residential and commercial buildings. It excels in delivering clean water efficiently and safely. Its corrosion resistance ensures that the water remains uncontaminated, maintaining its purity over time. This makes it a preferred option for copper plumbing tubes in homes and businesses.

Rigid copper tubing also performs well in HVAC systems. It handles the transfer of hot and cold water effectively, ensuring consistent temperature regulation. Its fire-resistant properties add an extra layer of safety, making it a dependable choice for critical systems.

When installing rigid copper pipe, you can use soldering or compression fittings to create leak-free connections. Its robust design ensures long-lasting performance, even in demanding environments. If you need a reliable material for water supply or HVAC systems, rigid copper tubing provides unmatched strength and dependability.

Key Differences Between Types of Copper Pipes and Tubing

Wall Thickness and Durability

The wall thickness of copper pipes and tubing plays a significant role in determining their durability and application. Rigid copper piping, such as Type K, L, and M, features varying wall thicknesses. Type K has the thickest walls, making it the most durable and suitable for high-pressure environments like underground water lines. Type L, with slightly thinner walls, is ideal for interior plumbing and HVAC systems. Type M, the thinnest of the three, works well for residential plumbing where lower pressure is sufficient.

In contrast, flexible copper tubing has thinner walls, which enhance its pliability but limit its ability to handle high pressure. This makes it better suited for low-pressure applications, such as refrigeration lines or gas supply systems. While rigid copper pipes excel in strength and longevity, flexible tubing offers adaptability in tight spaces or intricate layouts.

Tip: If your project demands long-term durability and resistance to high pressure, rigid copper piping is the better choice. For installations requiring flexibility, such as navigating obstacles, flexible copper tubing is more practical.

Cost and Affordability

Type L pipes, offering a balance between cost and durability, are slightly more expensive but provide greater versatility.

Flexible copper tubing, on the other hand, tends to be more expensive because of the annealing process that enhances its flexibility. Its higher cost often limits its use to specific applications where adaptability is essential, such as refrigeration or gas lines. Despite the price difference, flexible tubing can save money in labor costs by reducing the need for fittings and simplifying installation in complex layouts.

Consideration: Choose rigid copper piping for cost-effective solutions in standard plumbing systems. Opt for flexible tubing when the project requires maneuverability and reduced installation time.

Application-Specific Suitability

Rigid copper piping is the go-to choice for water supply lines, interior plumbing, and HVAC systems.

Flexible copper tubing shines in applications requiring bends and curves. It is widely used in refrigeration systems, where it efficiently transports refrigerants, and in gas lines, where its adaptability reduces the need for additional fittings. Its lightweight nature and ease of installation make it a preferred choice for intricate pathways or tight spaces.

Pro Tip: Evaluate the specific requirements of your project. Use rigid copper piping for stable, high-pressure systems. Choose flexible tubing for applications needing adaptability and quick adjustments.

By understanding these differences, you can make informed decisions that align with your project's needs, ensuring optimal performance and cost-effectiveness.

How to Choose the Right Type of Copper Pipe or Tubing

Selecting the best type of copper pipe or tubing requires careful consideration of your specific needs. By evaluating the application, durability, and budget, you can make an informed decision that ensures optimal performance and cost-effectiveness.

Consider the Application

The intended use of the copper pipe or tubing plays a crucial role in determining the right type. Different systems demand unique characteristics to function efficiently.

Plumbing Systems

For plumbing systems, the choice depends on whether the installation is for residential or commercial plumbing. Type L copper piping is often the best type of copper pipe for interior plumbing due to its balance of durability and versatility. It works well for both hot and cold water systems, making it a reliable option for homes and businesses. If cost is a concern, Type M copper piping offers a more affordable solution for residential plumbing, though it is less durable and unsuitable for high-pressure applications.

HVAC Systems

HVAC systems require pipes that can handle temperature fluctuations and pressure. Type L copper piping is a common choice for these systems because of its medium wall thickness and ability to withstand moderate pressure. For radiant heating or underground installations, Type K copper piping is the best type of copper pipe due to its thick walls and exceptional durability.

Industrial Use

Industrial applications often involve harsh conditions and high-pressure environments. Type K copper piping excels in these scenarios, offering unmatched strength and corrosion resistance. For non-pressurized systems, such as drainage or venting, DWV copper piping provides an efficient and cost-effective solution.

Tip: Always match the pipe type to the specific demands of your system to ensure safety and efficiency.

Evaluate Durability and Longevity Needs

Durability is a key factor when choosing copper pipes or tubing. If you need a long-lasting solution for high-pressure or underground installations, Type K copper piping is the most durable option. Its thick walls make it resistant to wear and tear, ensuring decades of reliable performance.

For general plumbing or HVAC systems, Type L copper piping offers a good balance between durability and cost. It can handle moderate pressure and is suitable for both residential and commercial plumbing. If your project involves low-pressure systems and budget constraints, Type M copper piping provides a cost-effective alternative, though it may not last as long as other types.

Flexible copper tubing, while less durable than rigid pipes, is ideal for applications requiring adaptability. Its pliability allows it to navigate tight spaces, making it a practical choice for refrigeration or gas lines.

Pro Tip: Consider the lifespan of the material and the conditions it will face to avoid frequent replacements or repairs.

Factor in Budget and Cost Considerations

Budget constraints often influence the choice of copper pipes or tubing. Type M copper piping is the most affordable option, making it suitable for residential plumbing projects with limited budgets. However, its thinner walls mean it is less durable and not ideal for high-pressure systems.

Type L copper piping, while slightly more expensive, offers greater strength and versatility. It is a cost-effective choice for most plumbing and HVAC applications. Type K copper piping, with its thick walls and superior durability, is the most expensive option. Its higher cost is justified for projects requiring maximum strength and longevity.

Flexible copper tubing typically costs more than rigid pipes due to the annealing process that enhances its flexibility. Despite the higher price, it can reduce labor costs by simplifying installation in complex layouts.

Consideration: Balance your budget with the performance requirements of your project to choose the most cost-effective solution.

By understanding the specific needs of your system, you can confidently select the best type of copper pipe or tubing. Whether for plumbing, HVAC, or industrial use, the right choice ensures efficiency, durability, and value for your investment.

Maintenance and Care for Copper Pipes and Tubing

Proper maintenance ensures the longevity and efficiency of copper pipes and tubing. By taking proactive steps, you can prevent common issues like corrosion and leaks, saving time and money in the long run. Below are essential practices to keep your copper piping and tubing in excellent condition.

Preventing Corrosion

Corrosion is one of the primary threats to copper pipes and tubing. While copper naturally resists corrosion, certain conditions can still cause damage over time. To prevent this, you should:

Monitor water quality: Hard water or water with high acidity can accelerate corrosion. Installing a water softener or pH balancer helps maintain optimal water conditions.

Avoid contact with dissimilar metals: When copper comes into contact with metals like steel or aluminum, galvanic corrosion can occur. Use dielectric unions or fittings to separate different metals in your plumbing system. Moisture can lead to external corrosion. Wrapping pipes with insulation reduces exposure to condensation and protects them from damage. Insulate pipes in humid areas.

Tip: Regularly check for signs of discoloration or greenish deposits on your pipes. These may indicate early stages of corrosion.

Regular Inspections and Repairs

Routine inspections play a crucial role in identifying potential problems before they escalate.

Inspect visible pipes: Look for leaks, discoloration, or bulges. These signs often indicate wear or damage.

Check joints and connections: Ensure that fittings remain secure and free from leaks. Loose connections can lead to water loss and reduced efficiency.

Address minor issues promptly: Small leaks or cracks can worsen over time. Repairing them early prevents costly replacements later.

For underground or concealed pipes, consider hiring a professional plumber for periodic assessments. Advanced tools like thermal imaging cameras can detect hidden leaks or weaknesses without invasive procedures.

Pro Tip: Schedule inspections at least once a year to ensure your system remains in top condition.

Tips for Extending Lifespan

Extending the lifespan of your copper pipes and tubing maximizes their value and reduces the need for frequent replacements. To achieve this, follow these best practices:

Maintain consistent water pressure: High water pressure can strain pipes and lead to premature wear. Install a pressure regulator to keep water pressure within safe limits.

Flush the system periodically: Sediment buildup can reduce efficiency and cause blockages. Flushing your plumbing system removes debris and keeps water flowing smoothly.

Upgrade aging systems: If your pipes are nearing the end of their lifespan, consider repiping. One of the advantages of repiping with copper is its durability and resistance to future issues, ensuring long-term reliability.

By implementing these strategies, you can significantly enhance the performance and durability of your copper piping and tubing. Proper care not only protects your investment but also ensures the safety and efficiency of your plumbing system.

Copper pipes and tubing offer unmatched versatility and durability for plumbing, HVAC, and industrial systems. By understanding the types—Type K, L, M, DWV, flexible, and rigid—you can make informed choices tailored to your needs. Always consider the application, required durability, and budget to ensure optimal performance. Regular maintenance, such as addressing green corrosion and preventing mineral buildup, extends their lifespan and reliability. With proper care, copper piping remains a dependable solution, delivering long-term value and efficiency for your projects.

FAQ

What are the main types of copper pipes, and how do they differ?

Copper pipes come in four primary types: Type K, Type L, Type M, and DWV. Each type serves specific purposes based on its wall thickness and durability:

Type K: Thickest walls, ideal for underground water lines and high-pressure systems.

Type L: Medium wall thickness, commonly used for interior plumbing and HVAC systems.

Type M: Thinner walls, suitable for residential plumbing with lower pressure needs.

DWV (Drain, Waste, Vent): Designed for non-pressurized systems like drainage and venting.

Understanding these differences helps you choose the right pipe for your project.

How do I decide between rigid and flexible copper tubing?

The choice depends on your application:

Rigid copper tubing: Best for water supply lines and HVAC systems. It offers strength and stability for fixed installations.

Flexible copper tubing: Ideal for refrigeration and gas lines. Its pliability allows it to navigate tight spaces and complex layouts.

If your project requires adaptability, go with flexible tubing. For durability and high-pressure systems, rigid tubing is the better option.

Why is copper a preferred material for plumbing and HVAC systems?

Copper offers several advantages:

Durability: It withstands high pressure and extreme temperatures.

Corrosion resistance: Copper resists rust and degradation, ensuring long-term reliability.

Thermal conductivity: It efficiently transfers heat, making it ideal for HVAC and radiant heating systems.

Environmental benefits: Copper is recyclable and does not release harmful chemicals.

These qualities make copper a dependable and eco-friendly choice for various applications.

How can I prevent corrosion in copper pipes?

To prevent corrosion, follow these steps:

Monitor water quality: Use a water softener or pH balancer to reduce acidity or hardness.

Avoid contact with dissimilar metals: Use dielectric unions to separate copper from other metals.

Insulate pipes: Protect pipes in humid areas with insulation to reduce condensation.

Regular maintenance ensures your copper pipes remain in excellent condition for decades.

What is the lifespan of copper pipes and tubing?

Copper pipes and tubing can last 50 to 60 years or more with proper care. Factors like water quality, installation practices, and maintenance influence their longevity. Regular inspections and preventive measures, such as addressing leaks and corrosion early, help maximize their lifespan.

Are copper pipes better than PEX pipes?

Copper pipes and PEX pipes each have strengths:

Copper pipes: Stronger, more durable, and suitable for both indoor and outdoor use. They resist corrosion and maintain water purity.

PEX pipes: More affordable and easier to install. However, they may not last as long and are less resistant to extreme conditions.

Choose copper for durability and long-term reliability. Opt for PEX if budget and ease of installation are priorities.

Do copper pipes require a lot of maintenance?

Copper pipes require minimal maintenance but benefit from regular inspections. Check for leaks, discoloration, or corrosion. Avoid chemical drain cleaners, as they can damage the pipes. Insulating pipes in cold areas also prevents freezing and extends their lifespan.

Can copper pipes handle extreme temperatures?

Yes, copper pipes excel in handling extreme temperatures. They perform well in both hot and cold water systems without cracking or degrading. This makes them ideal for HVAC systems, radiant heating, and other temperature-sensitive applications.

Are copper pipes environmentally friendly?

Copper pipes are highly sustainable. Copper is recyclable and does not release harmful chemicals into the environment. Its durability reduces the need for frequent replacements, minimizing waste. Choosing copper supports eco-friendly practices in construction and plumbing.

How do I choose the right type of copper pipe for my project?

Consider these factors:

Application: For underground water lines, use Type K. For interior plumbing, Type L is a versatile choice. For drainage, opt for DWV pipes.

Durability needs: Choose thicker-walled pipes like Type K for high-pressure systems.

Budget: Type M offers an economical option for residential plumbing.

Matching the pipe type to your specific requirements ensures safety, efficiency, and cost-effectiveness.

See Also

Exploring Various Copper Pipe Types And Soldering Techniques

Understanding Copper Pipe Sizes: An In-Depth Overview

Essential Tips For Purchasing Copper Pipe Coils