Your Ultimate Guide to 1/4 Inch Copper Pipe in Plumbing

In the realm of plumbing and HVAC systems, the significance of 1/4 inch copper pipes cannot be overstated. These slender yet robust conduits play a pivotal role in ensuring efficient water distribution and optimal performance of heating, ventilation, and air conditioning setups. As we delve into this comprehensive guide on the various uses of 1/4 inch copper pipe in plumbing and HVAC systems, expect to uncover the myriad applications and benefits associated with these versatile pipes. From potable water supply to refrigerant lines, 1/4 inch copper pipes are indispensable components that elevate the functionality of modern plumbing and HVAC systems.

Uses in Plumbing

When it comes to plumbing systems, 1/4 inch copper pipes play a crucial role in ensuring efficient water distribution. These slender yet durable conduits are widely utilized in both residential and commercial buildings for carrying water. Copper tubes are favored for their corrosion resistance and long lifespan, making them a popular choice post-World War II in the U.S.

Potable Water Supply

Benefits

Corrosion Resistance: One of the primary advantages of 1/4 inch copper pipes is their exceptional resistance to corrosion, ensuring a long service life.

Durability: Copper's robust nature guarantees longevity, providing a reliable solution for potable water transportation.

Non-Permeable Nature: The non-permeable quality of copper pipes prevents contamination, making them ideal for maintaining water quality.

Installation Methods

Soldering: Joining copper pipes through soldering creates strong and leak-proof connections.

Compression Fittings: Utilizing compression fittings offers a reliable method for connecting 1/4 inch copper pipes without the need for soldering.

Water-Distribution Manifolds

Efficiency Improvements

Installing smaller 1/4 inch pipes along with a new water-distribution manifold can significantly decrease the time it takes for hot water to reach faucets, enhancing overall efficiency.

The use of copper pipes ensures optimal flow rates and minimizes pressure losses within the plumbing system.

Cost Considerations

Longevity: Despite initial installation costs, the extended lifespan of copper pipes translates to cost savings over time due to reduced maintenance needs.

Energy Efficiency: Efficient water distribution achieved through 1/4 inch copper pipes can lead to energy savings by reducing heat loss in hot water supply lines.

Historical Uses

Ancient Applications

In ancient times, Egyptians utilized copper pipe around 2100 BC for various applications due to its malleability and durability. The historical significance of copper piping showcases its enduring value across civilizations.

Modern Developments

Today, modern advancements have further enhanced the utilization of copper pipes in plumbing systems. Innovations in manufacturing processes have improved the efficiency and reliability of 1/4 inch copper pipes, solidifying their position as indispensable components in contemporary construction practices.

Uses in HVAC Systems

Refrigerant Lines

Copper pipes, particularly 1/4 inch copper pipes, serve a vital role in HVAC systems when utilized as refrigerant lines. The inherent properties of copper, such as its durability and exceptional heat conductivity, make it an ideal choice for conveying refrigerants within air conditioning units and heat pumps.

Durability

The durability of 1/4 inch copper pipes is unparalleled in HVAC applications. Copper's resistance to corrosion and high pressure handling capabilities ensure the longevity and reliability of refrigerant lines. This durability minimizes the risk of leaks or system failures, providing uninterrupted operation of HVAC equipment.

Pressure Handling

1/4 inch copper pipes exhibit remarkable strength when subjected to varying pressures within HVAC systems. Their ability to withstand high pressure environments without compromising structural integrity makes them a preferred choice for refrigerant lines. This feature ensures optimal performance and efficiency of air conditioning units by maintaining consistent refrigerant flow.

Geothermal Systems

In geothermal heating and cooling systems, 1/4 inch copper pipes play a crucial role in facilitating the transfer of heat between the ground and the building. These systems utilize small-diameter copper tubes to circulate a heat exchange fluid through underground loops, harnessing the earth's stable temperature for efficient heating and cooling.

Vertical and Horizontal Applications

The versatility of 1/4 inch copper pipes allows for their installation in both vertical boreholes and horizontal trenches for geothermal systems. Whether vertically drilled deep into the ground or horizontally laid out in a grid pattern, copper tubes efficiently transfer thermal energy, contributing to sustainable heating and cooling solutions.

Environmental Benefits

By leveraging geothermal systems with 1/4 inch copper pipes, buildings can significantly reduce their carbon footprint while enhancing energy efficiency. The use of copper tubes promotes eco-friendly practices by harnessing renewable geothermal energy sources for heating and cooling purposes, thereby minimizing reliance on traditional fossil fuels.

Installation and Maintenance

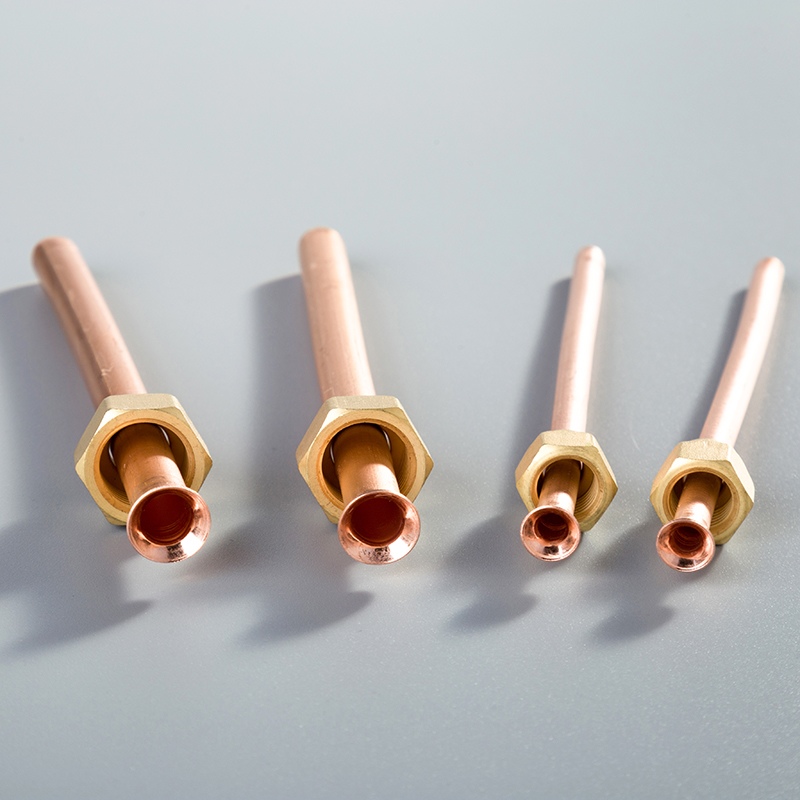

Compression Fittings

Advantages

When it comes to 1/4 inch copper pipes, utilizing compression fittings offers a multitude of advantages for seamless installations. The inherent design of compression fittings allows for a secure and leak-proof connection between pipes, eliminating the need for complex soldering techniques. This simplicity in assembly not only saves time but also ensures a reliable joint that withstands high pressure and temperature variations. The versatility of compression fittings makes them suitable for various applications, from potable water supply lines to HVAC systems, providing a cost-effective solution for joining 1/4 inch copper pipes with ease.

Step-by-Step Guide

For those embarking on the installation journey of 1/4 inch copper pipes using compression fittings, a step-by-step guide can be invaluable in achieving a successful outcome:

Prepare the Pipes: Cut the copper pipes to the required length using a pipe cutter, ensuring clean and burr-free edges.

Deburr and Clean: Use a deburring tool to remove any rough edges or imperfections from the cut ends of the pipes. Thoroughly clean both the exterior and interior surfaces to promote optimal adhesion.

Assemble the Fittings: Slide the compression nut followed by the compression ring onto one end of the pipe. Insert the pipe into the fitting until it reaches the tube stop.

Tighten Securely: Using two wrenches, grip the body of the fitting and tighten the compression nut until snug. Avoid over-tightening to prevent damage to the fitting or pipe.

Check for Leaks: Once assembled, conduct a pressure test to ensure there are no leaks at the joints. Tighten any connections if necessary to achieve a watertight seal.

Maintenance Tips

Regular Inspections

To uphold the integrity and functionality of 1/4 inch copper pipes, regular inspections are paramount in identifying potential issues before they escalate into major problems. Establishing a routine inspection schedule enables homeowners and professionals to detect leaks, corrosion, or damage promptly, ensuring continuous operation of plumbing and HVAC systems without disruptions.

Common Issues and Solutions

Despite their durability, 1/4 inch copper pipes may encounter common issues that require timely intervention:

Corrosion: Address corrosion by applying epoxy coatings or utilizing anti-corrosive treatments to protect copper surfaces from degradation.

Leaks: In case of leaks, assess joints for loose fittings or damaged components, tightening connections as needed or replacing faulty parts.

Blockages: Clear blockages within copper pipes using appropriate tools or chemical solutions designed for pipe maintenance.

By adhering to these maintenance tips and promptly addressing any issues that arise, individuals can prolong the lifespan of 1/4 inch copper pipes while ensuring optimal performance in plumbing and HVAC systems.

To summarize, 1/4 inch copper pipes are essential for efficient water distribution and HVAC systems due to their durability and corrosion resistance.

In the future, expect an increased integration of 1/4 inch copper pipes in sustainable construction practices for eco-friendly solutions.

Homeowners and professionals should prioritize regular maintenance checks to ensure the longevity and optimal performance of 1/4 inch copper pipes.

See Also

The Definitive Manual for Purchasing 1/4 3/8 Copper Tubing Rolls

The Indispensable Handbook for 3-Inch Copper Tube Connectors

The Comprehensive Handbook for Choosing 1/4 3/8 Copper Tubing Rolls

The Ultimate Manual for Premium Copper Tube Connectors

The Ultimate Handbook for Copper Tubing Varieties and Soldering