Your Ultimate Purchasing Guide for Copper Pipe Coils

Selecting the right Copper Pipe Coils is paramount for various applications, from residential to commercial. This blog aims to provide a comprehensive Purchasing Guide on making informed decisions when purchasing these essential components. By understanding the nuances of White PE Insulation and key considerations in diameter selection, readers will be equipped to choose the most suitable copper pipe coils for their specific needs.

Understanding Copper Pipe Coils

When it comes to Copper Pipe Coils, understanding the different types and applications is crucial for making informed decisions. Let's delve into the specifics of each type and explore their respective benefits.

Types of Copper Pipe Coils

Type L Copper Tubing

Type L Copper Tubing is known for its medium weight and versatility. It is commonly used in various applications due to its durability and corrosion resistance. This type of tubing is ideal for projects that require a reliable and long-lasting solution.

Type M Copper Tubing

On the other hand, Type M Copper Tubing is thinner compared to Type L and is typically used underground or for light domestic water lines. While it may not be as heavy-duty as Type L, it serves well in specific scenarios where a lighter option is preferred.

Applications of Copper Pipe Coils

Residential Uses

In residential settings, Copper Pipe Coils play a vital role in plumbing systems, HVAC installations, and even refrigeration units. The durability of copper makes it a popular choice among homeowners looking for reliable piping solutions that can withstand varying conditions.

Commercial Uses

Within commercial environments, the versatility of Copper Pipe Coils shines through in various applications such as industrial machinery, air conditioning systems, and refrigeration units. The corrosion resistance of copper ensures longevity and efficiency in demanding settings.

Benefits of Copper Pipe Coils

Durability

One of the primary advantages of Copper Pipe Coils is their exceptional durability. Whether used in residential or commercial settings, copper tubing can withstand high pressure, temperature fluctuations, and external elements without compromising its structural integrity.

Corrosion Resistance

Another key benefit of Copper Pipe Coils is their inherent resistance to corrosion. This property ensures that the piping remains intact over time, reducing the risk of leaks or damage due to rust or chemical reactions. The longevity provided by copper coils ultimately leads to cost savings and peace of mind for users.

Importance of White PE Insulation

In the realm of Copper Pipe Coils, the significance of White PE Insulation cannot be overstated. This insulation serves a dual purpose, acting as a shield against corrosion and providing essential thermal protection for the coils.

Role of White PE Insulation

When it comes to Corrosion Prevention, White PE Insulation acts as a barrier between the copper coils and external elements that could potentially cause deterioration. By creating a protective layer, it safeguards the integrity of the coils, ensuring longevity and optimal performance.

For Thermal Protection, White PE Insulation plays a crucial role in maintaining consistent temperatures within the piping system. By minimizing heat loss or gain, it enhances the overall efficiency of the coils, contributing to energy savings and operational effectiveness.

Insulation Thickness

When considering Insulation Thickness for copper pipe coils, several Factors to Consider come into play. The thickness of the insulation directly impacts its effectiveness in preventing heat transfer and maintaining desired temperatures. Factors such as environmental conditions, application requirements, and insulation quality should all be evaluated to determine the most suitable thickness for optimal performance.

Moreover, assessing the Environmental Impact of insulation choices is essential in promoting sustainability and eco-conscious practices. Opting for high-quality insulation materials not only ensures efficient operation but also reduces energy consumption and minimizes environmental footprint.

Purchasing Guide for Copper Pipe Coils

When embarking on the journey of selecting Copper Pipe Coils, it is essential to consider key factors that will ensure a successful purchase. By focusing on aspects such as Diameter Selection and Insulation Thickness, individuals can make informed decisions that align with their specific requirements.

Key Considerations

Diameter Selection

Selecting the appropriate Diameter for your copper pipe coils is a critical step in the purchasing process. Different applications necessitate varying diameters to optimize performance and efficiency. To guide this decision, consider the specific needs of your project and consult with industry experts if necessary.

Insulation Thickness

The Thickness of insulation plays a pivotal role in safeguarding the longevity and functionality of your copper pipe coils. Optimal insulation thickness ensures enhanced thermal protection and corrosion prevention, contributing to the overall durability of the system. Evaluate environmental factors and application demands when determining the ideal insulation thickness for your installation.

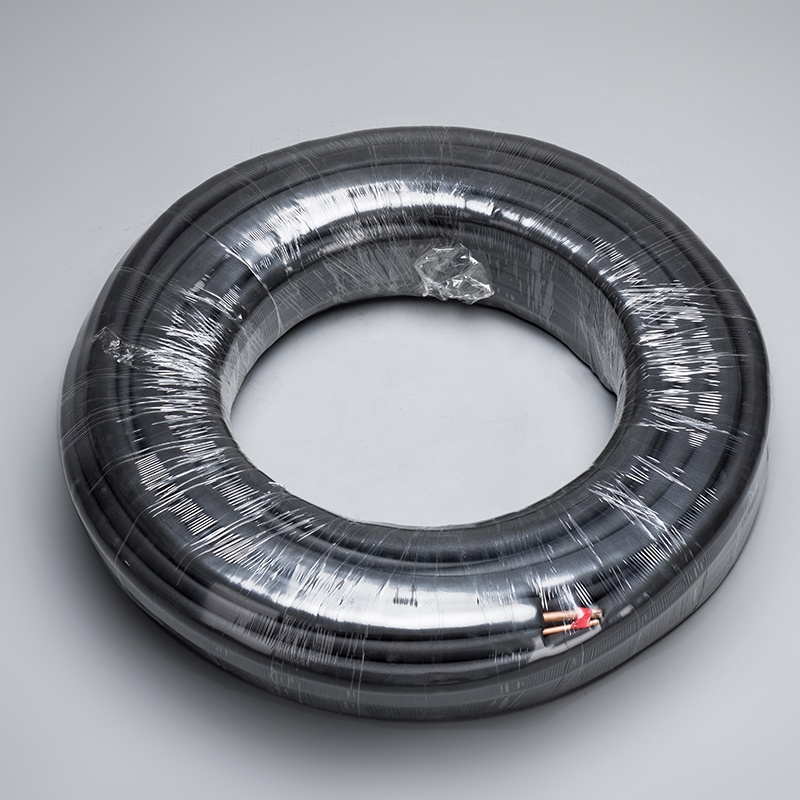

Components of a Copper Piping Kit

Pipe Assembly

A comprehensive Copper Piping Kit typically includes essential components such as pipe assembly, insulation, and communication cable. The pipe assembly serves as the backbone of your installation, providing structural support and ensuring seamless connectivity between components. When selecting a piping kit, prioritize high-quality materials to guarantee reliability and longevity.

Communication Cable

Incorporating a reliable Communication Cable into your copper piping kit is crucial for facilitating data transmission and system integration. This component enables seamless communication between various elements of your setup, enhancing overall operational efficiency. Prioritize compatibility and durability when choosing a communication cable to support the functionality of your copper pipe coils effectively.

Installation Tips

Following Instructions

Adhering to manufacturer instructions during the installation process is paramount to ensure optimal performance and safety. Detailed guidelines provided by manufacturers offer valuable insights into best practices for installing copper pipe coils correctly. By following these instructions meticulously, individuals can mitigate risks and maximize the efficiency of their systems.

Ensuring Safety

Prioritizing safety measures throughout the installation of copper pipe coils is non-negotiable. Implementing proper safety protocols, such as wearing protective gear and securing components adequately, safeguards against potential hazards during installation. By emphasizing safety at every stage of the process, individuals can create a secure environment for themselves and others involved in the project.

Summarize the significance of selecting the right Copper Pipe Coils based on specific needs and applications.

Recommend prioritizing durability and corrosion resistance when choosing Copper Pipe Coils for long-term reliability.

Consider future advancements in insulation technology to enhance thermal efficiency and environmental sustainability.

See Also

The Definitive Guide to Purchasing Copper Pipe Coils

The Comprehensive Guide to Buying Copper Pipe Coils

The Ultimate Guide to Purchasing 1/4 3/8 Copper Pipe Coils

The Comprehensive Guide to Choosing 1/4 3/8 Copper Pipe Coils