Your Ultimate Guide to Twin Copper Pipe Coil Installation

Write a compliance manual for twin copper pipe coils installation in residential settings to ensure efficient and durable HVAC systems. Understanding the significance of this process is essential for homeowners and professionals alike. This section provides an insightful overview of the meticulous steps involved in installing these coils, emphasizing the importance of precision and adherence to guidelines. Proper installation not only enhances system performance but also prolongs its lifespan, offering long-term benefits to users.

Importance of Proper Installation

Longevity and Durability

Material Benefits

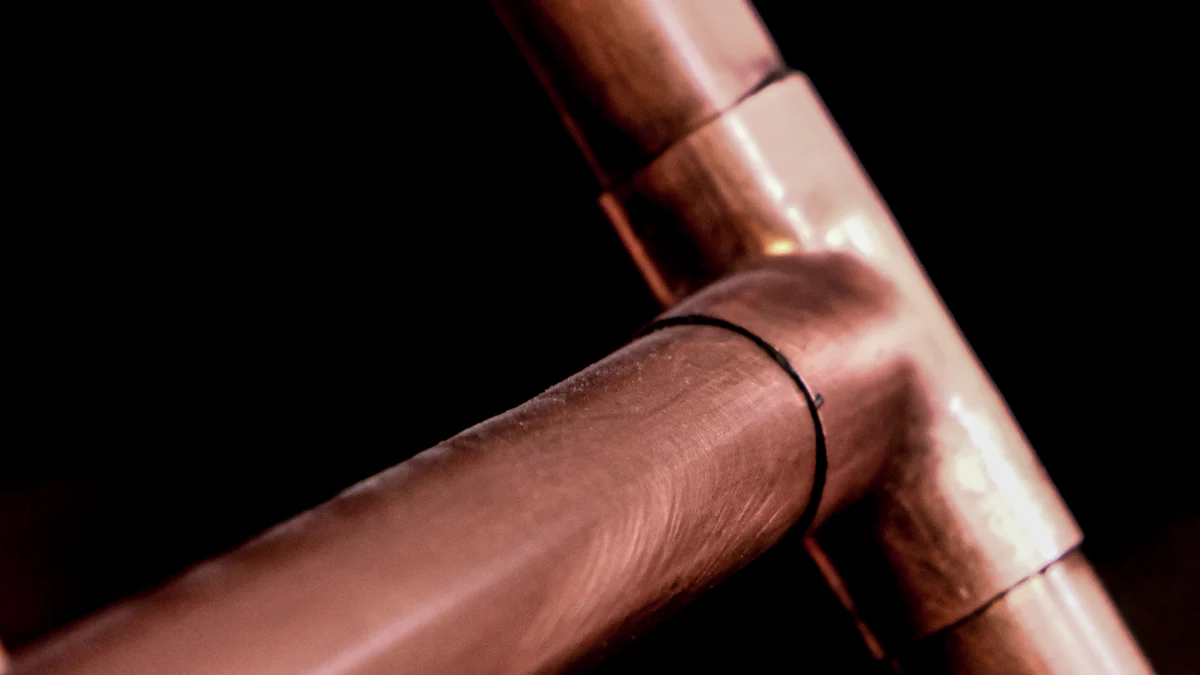

Copper tube is often used for sinuous coil installation due to its long-lasting properties.

The material benefits of using copper tubes include enhanced durability and longevity, ensuring a reliable HVAC system for years to come.

Customers find the crimping pliers easy to use and time-saving, which further emphasizes the importance of proper installation techniques.

Cost Efficiency

Proper installation of twin copper pipe coils not only ensures longevity but also contributes to cost efficiency in the long run.

Using high-quality materials like copper reduces the need for frequent replacements, saving homeowners money on maintenance and repair costs over time.

Benefits of soft and pH-neutral water include longer service life of plumbing systems and appliances, offsetting the initial investment through reduced soap and detergent usage.

Preventing Malfunctions

Common Issues

Improper installation can lead to common issues such as leaks, blockages, or inefficient cooling/heating performance.

Following precise installation guidelines is crucial in preventing these common issues that may arise from substandard workmanship.

Solutions

By adhering strictly to manufacturer instructions and industry best practices during installation, many potential malfunctions can be avoided.

Regular maintenance checks post-installation can help identify any issues early on, allowing for prompt solutions before they escalate into costly problems.

Ensuring Safety

Electrical Components

Installation of air-conditioning equipment should be done with caution due to electrical components involved in the system.

Compliance tools are available for builders seeking approval for compliance software in residential settings, ensuring safety standards are met throughout the process.

System Pressure

Proper drainage piping installation is crucial to prevent water damage in residential settings caused by excessive system pressure.

Ventilation requirements should be considered during field-installed condensate piping installations to maintain safe operating pressures within the system.

Step-by-Step Installation Guide

Preparation

Tools and Materials

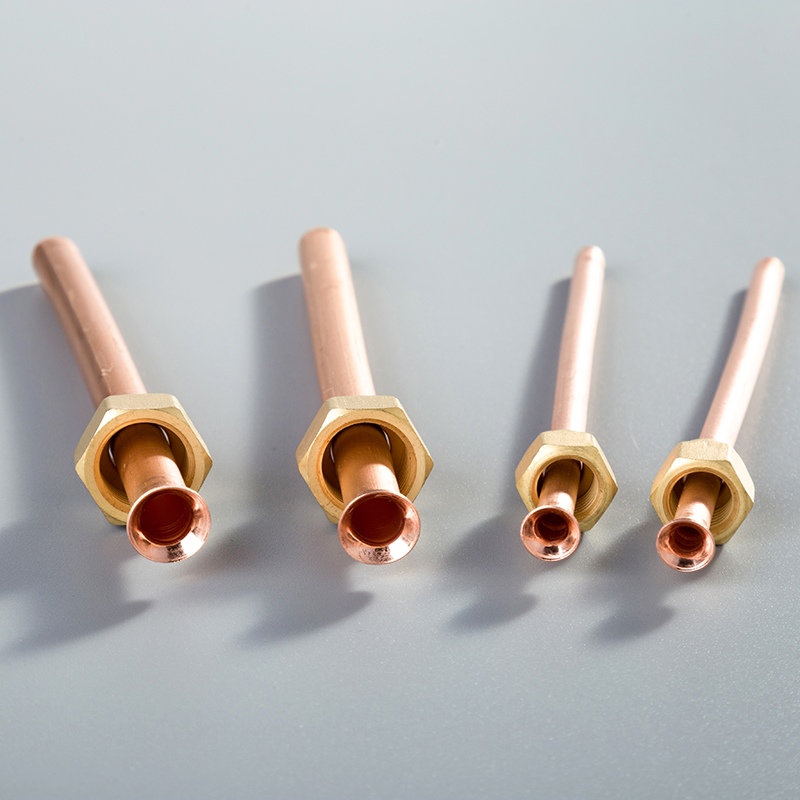

Gather the necessary tools for the installation process, including a pipe cutter, deburring tool, flux, solder, and a propane torch.

Ensure you have the required materials on hand, such as copper pipes, fittings, and insulation to prevent heat loss.

Site Inspection

Begin by inspecting the installation site to assess the layout and determine the best placement for the twin copper pipe coils.

Check for any obstacles or obstructions that may hinder the installation process and make adjustments as needed.

Installation Process

Measuring and Cutting

Measure the length of copper pipe needed for each coil accurately using a measuring tape.

Use a pipe cutter to cut the copper tubes to the correct dimensions with precision to ensure a proper fit.

Connecting Pipes

Clean both ends of the pipes thoroughly using a deburring tool to remove any burrs or rough edges.

Apply flux to the cleaned surfaces and use a propane torch to solder the connections securely.

Securing and Testing

Secure the twin copper pipe coils in place using appropriate fasteners to prevent movement or shifting.

Conduct pressure tests on the installed coils to ensure there are no leaks or weak points in the system.

Post-Installation

Inspection

After completing the installation process, conduct a thorough inspection of all connections and joints for any signs of leakage.

Verify that all components are securely fastened and properly aligned to guarantee optimal performance.

Maintenance Tips

Regularly check for any signs of corrosion or damage on the copper pipes and address them promptly.

Insulate exposed pipes to prevent heat loss and improve energy efficiency in your HVAC system over time.

By following these step-by-step guidelines meticulously, you can ensure a successful twin copper pipe coil installation that enhances your HVAC system's efficiency and longevity while minimizing potential issues down the line. Remember that attention to detail during each phase of installation is key to achieving optimal results in your residential setting.

Compliance and Safety

To ensure the successful installation of twin copper pipe coils in residential settings, it is imperative to write a compliance manual for twin copper pipe coils installation that aligns with regulatory standards and best practices. By adhering to these guidelines, homeowners and professionals can guarantee the efficiency and safety of their HVAC systems.

Regulatory Standards

Gas piping systems: The regulatory standards for gas piping systems dictate design pressure limitations, leakage testing procedures, and appliance connections. These requirements are crucial for maintaining the integrity of fuel gas piping attached to manufactured homes.

Installation Handbook: Hot and Cold Water-Distribution Systems: This handbook outlines minimum installation requirements, emphasizing the use of metallic or approved materials for water distribution systems. Compliance with these standards ensures the reliability and longevity of plumbing installations.

Best Practices

When handling materials during the installation process, prioritize safety protocols to prevent accidents or damage. Proper training on material handling techniques can significantly reduce risks associated with working on HVAC systems.

Ventilation requirements play a vital role in maintaining optimal system performance. Adequate airflow around condensate piping installations helps regulate system pressure and prevents potential issues related to restricted airflow.

By incorporating regulatory standards into the compliance manual and following best practices during installation, individuals can safeguard their HVAC systems against malfunctions and ensure long-term efficiency in residential settings.

In summary, the installation of twin copper pipe coils demands precision and adherence to guidelines for optimal performance.

Following manufacturer instructions and industry best practices is crucial for longevity and efficiency.

Future considerations should include regular maintenance checks and compliance with regulatory standards.

See Also

The Definitive Guide to Purchasing Copper Pipe Coils

The Complete Handbook on Contemporary Copper Pipe Coil Methods

The Ultimate Handbook for Buying Copper Pipe Coils