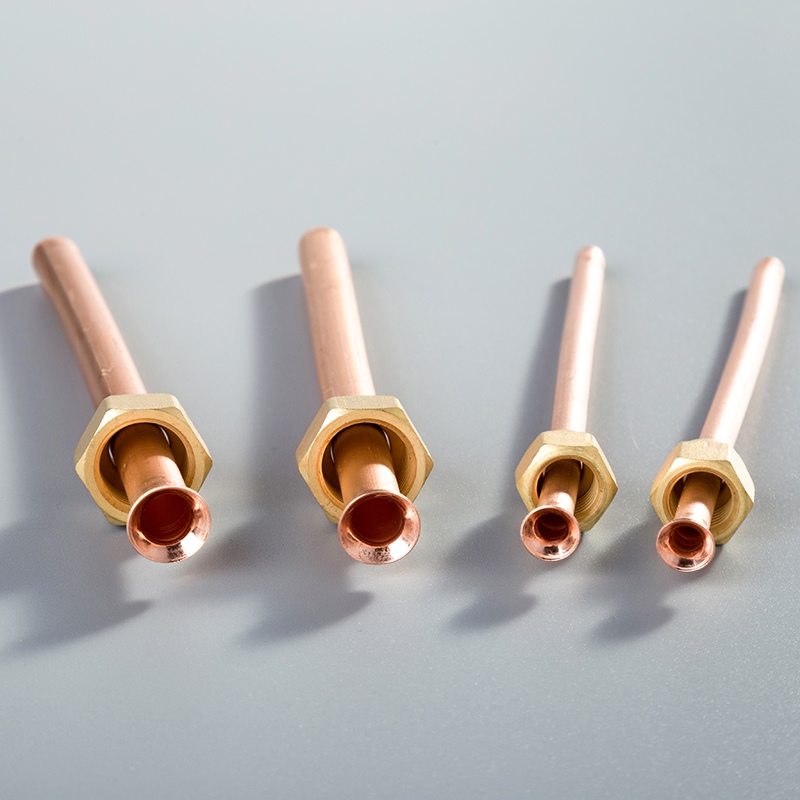

Understanding the 4 Types of Copper Pipes

Copper pipes, essential in both residential and commercial construction, play a vital role in various systems. The four main types, Type K, Type L, Type M, and DWV, each serve specific purposes due to their unique characteristics. Copper's resistance to corrosion makes it ideal for soil, waste, vent, solar, and storm drainage piping systems. Plumbers emphasize the importance of choosing between plastic and copper pipes based on project needs rather than personal preference. Knowing how to solder copper pipe and using a copper pipe cutter or a copper pipe crimping tool can significantly impact the efficiency and durability of the installation.

Type K Copper Pipe

Characteristics

Thickness and durability: Type K copper pipes are known for their exceptional thickness, providing unmatched durability and strength. The robust walls of these pipes make them highly resistant to external pressures and corrosion, ensuring a long-lasting plumbing solution.

Color coding (green): Easily identifiable by their distinctive green color, Type K copper pipes stand out among the various types. This color coding simplifies the selection process, allowing plumbers to quickly distinguish Type K pipes from others.

Uses

Underground installations: Due to their superior strength and durability, Type K copper pipes are commonly used for underground installations. Whether it's for water supply lines or drainage systems, these pipes excel in withstanding the harsh conditions below the surface.

Main water lines: One of the primary applications of Type K copper pipes is in main water lines. Their robust construction and corrosion resistance make them ideal for carrying large volumes of water efficiently and reliably.

Tools

Copper pipe cutter: When working with Type K copper pipes, a reliable copper pipe cutter is essential for achieving precise cuts without causing damage to the material. This tool ensures clean edges, facilitating seamless connections during installation.

Copper pipe crimping tool: For secure fittings and joints in Type K copper pipe installations, a copper pipe crimping tool is indispensable. This tool allows plumbers to create strong connections that prevent leaks and ensure the integrity of the plumbing system.

Type L Copper Pipe

Characteristics

Thickness and versatility: Type L copper pipes are recognized for their moderate thickness, offering a balance between durability and flexibility. The versatile nature of these pipes allows them to adapt to various plumbing needs without compromising strength.

Color coding (blue): Identified by their distinctive blue color, Type L copper pipes provide a visual cue for plumbers during installations. This color scheme simplifies the differentiation process, ensuring the correct selection for specific applications.

Uses

Interior plumbing: Type L copper pipes are commonly utilized in interior plumbing systems due to their reliable performance and adaptability. From residential bathrooms to commercial kitchens, these pipes effectively transport water and maintain structural integrity.

HVAC systems: In HVAC (Heating, Ventilation, and Air Conditioning) setups, Type L copper pipes play a crucial role in facilitating the circulation of refrigerants and maintaining optimal temperature control. Their durability and corrosion resistance make them ideal for demanding HVAC environments.

Tools

Copper pipe cutter: A precise copper pipe cutter is essential when working with Type L copper pipes to ensure accurate cuts that promote seamless connections. This tool enables plumbers to achieve clean edges for secure fittings in plumbing installations.

How to solder copper pipe: Understanding the soldering process is vital for joining Type L copper pipes effectively. Proper soldering techniques ensure leak-free connections and enhance the overall efficiency of the plumbing system.

Type M Copper Pipe

Characteristics

Copper pipes of Type M are distinguished by their thinner walls, providing a lightweight yet durable solution for various plumbing needs. The color coding in a vibrant red hue makes them easily identifiable among other types, simplifying the selection process for plumbers.

Thinner walls

The thinner walls of Type M copper pipes offer flexibility and ease of handling during installations. Despite their lighter build, these pipes maintain structural integrity and reliability, ensuring efficient water flow without compromising performance.

Color coding (red)

The bold red color distinguishes Type M copper pipes from their counterparts, allowing for quick recognition and accurate application. This visual cue aids plumbers in selecting the appropriate pipe type for specific residential plumbing or low-pressure systems.

Uses

Residential plumbing projects benefit from the versatility of Type M copper pipes, which excel in transporting water efficiently within homes. Their lightweight design and corrosion resistance make them ideal for various household plumbing applications.

Low-pressure applications

In scenarios where low-pressure systems are prevalent, such as certain irrigation setups or specific residential plumbing fixtures, Type M copper pipes offer a reliable solution. Their durability and cost-effectiveness make them a preferred choice for such applications.

Tools

When working with Type M copper pipes, utilizing essential tools ensures precise installations and secure connections throughout the plumbing system.

Copper pipe cutter

A high-quality copper pipe cutter is indispensable for achieving clean and accurate cuts on Type M copper pipes. This tool facilitates seamless installations by providing smooth edges that promote leak-free connections.

Copper pipe crimping tool

For creating strong and reliable joints in Type M copper pipe installations, a dependable copper pipe crimping tool is essential. This tool enables plumbers to secure fittings effectively, enhancing the overall performance and longevity of the plumbing system.

DWV Copper Pipe

Characteristics

Thin walls

DWV copper pipes are characterized by their thin walls, which provide flexibility and ease of handling during installations. Despite the lightweight construction, these pipes maintain structural integrity and reliability, ensuring efficient water flow without compromising performance.

Color coding (yellow)

Identified by their distinctive yellow color, DWV copper pipes stand out among the various types. This color scheme simplifies the selection process for plumbers, allowing for quick recognition and accurate application in drainage systems and waste and vent systems.

Uses

Drainage systems

In drainage systems, DWV copper pipes play a crucial role in efficiently removing wastewater from residential and commercial buildings. The thin walls of these pipes facilitate the smooth flow of liquids, preventing clogs and ensuring proper waste disposal.

Waste and vent systems

DWV copper pipes are commonly used in waste and vent systems to eliminate sewage gases while allowing air to enter the plumbing system. These pipes effectively channel waste materials away from the building, maintaining a hygienic environment for occupants.

Tools

Copper pipe cutter

When working with DWV copper pipes, a reliable copper pipe cutter is essential for achieving precise cuts that ensure seamless installations. This tool enables plumbers to create clean edges on the pipes, promoting secure connections throughout the plumbing system.

How to solder copper pipe

Understanding how to solder copper pipe is vital for joining DWV copper pipes effectively. Proper soldering techniques guarantee leak-free connections, enhancing the overall efficiency and longevity of the plumbing system.

Copper water pipes are less susceptible to corroding and last a long time due to their rigid nature. They resist degrading when exposed to ultraviolet light and are naturally resistant to bacteria growth.

Plastic pipes or PEX tubing offer some great advantages. PEX is many plumbers' first choice for re-piping jobs. Plastic pipes are flexible and less rigid than copper, making them slightly more susceptible to contamination.

Copper tubes according to ASTM 306 are used in various piping systems including soil, waste, vent, solar, and storm drainage. Copper tubes are versatile and used in different applications.

See Also

The Definitive Manual on Copper Pipe Varieties and Soldering

Decoding Copper Pipe Dimensions: An In-Depth Handbook

5 Crucial Factors in Selecting the Correct Copper Pipe Width

5 Key Pointers for Utilizing 1/4 Copper Pipe Connectors

5 Vital Copper Pipe Dimensions Every Plumber Must Understand