What Happens When AC Copper Pipes Aren't Insulated?

When it comes to air conditioning systems, the importance of insulation cannot be overstated. Without proper insulation, a myriad of issues can arise, especially when it concerns uninsulated AC copper pipes. This blog post aims to delve into what happens if you don't insulate air conditioner copper pipes and the consequences that stem from neglecting to insulate these crucial components of your AC system.

The Role of Insulation in AC Systems

Why Insulation is Essential

Preventing Energy Loss

Proper insulation of ductwork can lower electric bills and improve HVAC system performance.

It's better to turn off the AC when not in use, as leaving the AC unit on all the time is not cost-effective according to valid studies.

Reducing Condensation

Insulation also helps keep ductwork sanitary and improves indoor air quality.

Saving energy, reducing maintenance, and improving resilience in Air Handling Units.

Enhancing System Efficiency

Insulating AC systems can significantly improve their efficiency.

Efficient systems lead to lower energy consumption and reduced operational costs.

Consequences of Uninsulated AC Copper Pipes

When insulating air conditioner copper pipes is neglected, the consequences can be significant. Let's explore the outcomes of failing to insulate air conditioner copper pipes properly.

Increased Energy Consumption

Running an AC system with uninsulated copper pipes can lead to a surge in energy consumption.

This spike in energy usage translates to higher utility bills for the consumer.

Higher Utility Bills

Insulating the copper pipes helps maintain energy efficiency and keeps utility costs in check.

Without proper insulation, the AC system works harder, resulting in increased electricity expenses.

Strain on the AC System

Uninsulated copper pipes put additional strain on the entire AC system.

The system must compensate for the heat loss due to lack of insulation, leading to potential wear and tear.

Moisture and Condensation Issues

Lack of insulation on copper pipes can create moisture-related problems within the AC system.

This moisture buildup poses a risk of mold and mildew formation in the surrounding areas.

Risk of Mold and Mildew

Mold and mildew thrive in damp environments caused by condensation on uninsulated copper pipes.

Proper insulation prevents this issue, safeguarding against mold growth and its associated health risks.

Potential Water Damage

Condensation from uninsulated copper pipes can result in water damage to walls, ceilings, or floors.

Insulation acts as a protective barrier, preventing potential water leaks and subsequent structural damage.

Reduced System Efficiency

Inefficient cooling due to uninsulated copper pipes leads to longer cooling times for your space.

This inefficiency also results in inconsistent temperature control throughout your home or office.

Longer Cooling Times

Without proper insulation, cool air loses its temperature as it travels through uninsulated copper pipes.

This extended cooling process delays achieving optimal room temperatures efficiently.

Inconsistent Temperature Control

The lack of insulation causes temperature fluctuations within different areas of a room or building.

Insulating these copper pipes ensures consistent cooling performance across all spaces.

How to Properly Insulate AC Copper Pipes

Choosing the Right Insulation Material

Factors to Consider

Product Information:

Radiant Barriers: Radiant barriers work best when combined with lower levels of insulation, maximizing energy savings. However, their effectiveness decreases when paired with high levels of insulation.

Product Information:

Duct Insulation: The R-value of insulation determines its resistance to heat flow, crucial for maintaining indoor temperatures. Higher R-values indicate more efficient insulation.

Pros and Cons of Different Materials

Foam Insulation:

Pros:

Excellent thermal resistance.

Easy to install and handle.

Resistant to moisture.

Cons:

Can be more expensive than other options.

Rubber Insulation:

Pros:

Flexible and durable material.

Provides soundproofing benefits.

Resistant to mold growth.

Cons:

May require professional installation due to complexity.

Fiberglass Insulation:

Pros:

Cost-effective solution.

Lightweight and easy to transport.

Offers good thermal performance.

Cons:

Prone to moisture absorption if not properly sealed.

Step-by-Step Insulation Process

Measuring and Cutting Insulation

Measure the length of the copper pipes accurately using a tape measure.

Cut the chosen insulation material based on the measurements taken, ensuring a snug fit around the pipes.

Securing the Insulation

Wrap the cut insulation around the copper pipes firmly but without compressing it too tightly.

Use adhesive or tape designed for insulation materials to secure the covering in place effectively.

Inspecting for Gaps and Sealing

Check for any gaps or openings in the insulation after securing it around the copper pipes.

Seal any exposed areas using additional insulation or specialized sealants to prevent heat loss or condensation buildup.

By selecting suitable insulation materials and following a meticulous installation process, you can ensure optimal efficiency and performance from your AC system while preventing potential issues associated with uninsulated copper pipes.

In wrapping up, ensuring that AC copper pipes are properly insulated is paramount for maintaining an efficient air conditioning system. Neglecting to insulate these pipes can result in increased energy consumption and potential issues like moisture-related problems and reduced system efficiency. To uphold the longevity and effectiveness of your AC unit, taking action to insulate air conditioner copper pipes is crucial. By choosing the right insulation materials and following a meticulous installation process, you can safeguard against these detrimental consequences and enjoy optimal cooling performance.

See Also

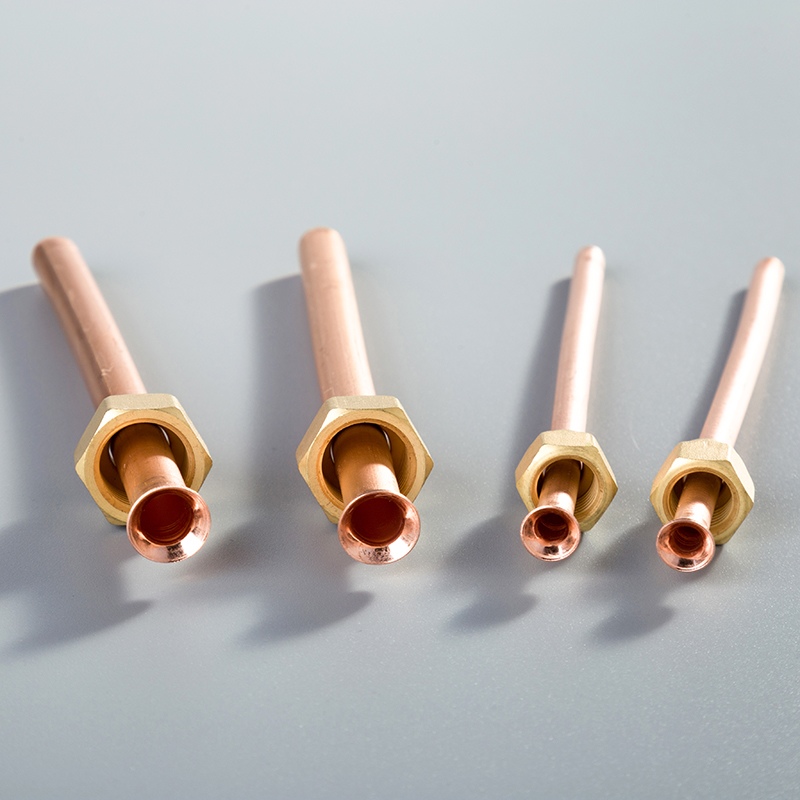

Exploring the Enchantment of Copper Pipes in Air Conditioning

Benefits of Selecting Copper Pipes for Air Conditioners

Exploring Optimal Insulation for Copper Pipes

Enhance AC Efficiency with Copper Pipes Insulation Tips

The Revolutionary Impact of Copper Pipes on Air Conditioning