Guide to Choosing the Right Thickness for AC Copper Pipes

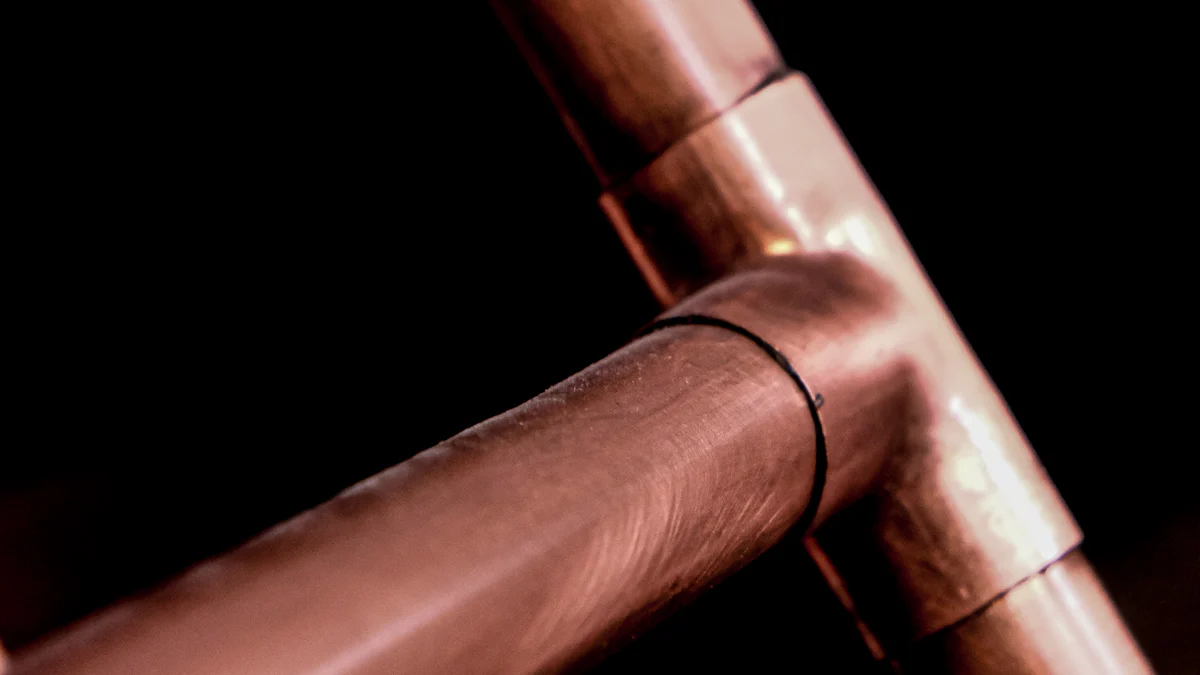

Copper pipes play a pivotal role in air conditioning systems, offering unparalleled heat transfer, durability, and corrosion resistance. Thicker-walled pipes, though pricier, provide enhanced strength essential for long-term performance. Insulated copper pipes, such as an ac copper pipe sleeve, effectively prevent condensation, thereby boosting energy efficiency. Regular maintenance is key to ensuring optimal functionality and longevity of these essential components. When it comes to selecting the right ac copper pipe thickness, understanding the nuances is crucial for an efficient HVAC system design. Consulting an ac copper pipe size list can help in choosing the appropriate ac copper pipe set for your needs.

Types of Copper Pipes

Common Types

Type K

Type K copper pipes are known for having the thickest wall among common types of copper pipes. They are primarily used in applications such as water distribution, fire protection, oil systems, and HVAC setups. These pipes are recommended for main water lines and underground installations due to their exceptional strength that enables them to withstand high pressure from backfilled earth in trenches.

Type L

Type L copper pipes are commonly utilized in various applications, including plumbing and HVAC systems. These thick-walled pipes offer increased strength and durability, making them suitable for air conditioning systems operating at high pressures and temperatures. Type L pipes are often preferred for larger commercial or industrial air conditioning applications.

Type M

Type M copper pipes have a medium wall thickness and are lighter compared to Type L pipes. They find common usage in plumbing and some HVAC applications, especially in residential air conditioning systems or smaller commercial setups that operate at lower pressures and temperatures. Despite being lighter, Type M pipes maintain sufficient durability for their designated applications.

AC Copper Pipe Set

When considering an ac copper pipe set, it is essential to evaluate the specific requirements of your air conditioning system. Different types of copper pipes offer varying levels of strength, durability, and suitability based on the system's operational demands. Selecting the appropriate ac copper pipe set ensures optimal performance and longevity of your HVAC setup.

AC Copper Pipe Size List

Consulting an ac copper pipe size list is crucial when designing or upgrading an air conditioning system. The correct sizing of copper pipes directly impacts the efficiency and effectiveness of the HVAC setup. By referencing an ac copper pipe size list, you can accurately select the right dimensions for your system's needs, ensuring proper functionality and performance.

Choosing the Right Thickness

When selecting the appropriate AC Copper Pipe Thickness for your air conditioning system, it is crucial to consider specific factors that directly impact performance and longevity. HVAC professionals or experienced contractors recommend evaluating the Refrigerant Type and System Pressure to determine the optimal thickness for your copper pipes.

Factors to Consider

Refrigerant Type: Different refrigerants have varying requirements when it comes to copper pipe thickness. Understanding the specific refrigerant used in your air conditioning system is essential for selecting the right copper pipe thickness. For instance, systems utilizing R410A or R32 refrigerants typically require a minimum thickness of 0.61mm for optimal performance.

System Pressure: The operating pressure of your air conditioning system plays a significant role in determining the suitable copper pipe thickness. Higher system pressures necessitate thicker-walled pipes to withstand the stress and ensure durability over time. Thicker-walled copper pipes, such as Type L, offer increased strength and reliability for systems operating at elevated pressures.

AC Copper Pipe Thickness

Choosing the correct AC Copper Pipe Thickness is vital for ensuring efficient heat transfer and structural integrity within your HVAC setup. Thicker-walled pipes provide enhanced durability and resistance to corrosion, extending the lifespan of your air conditioning system. Consulting with HVAC professionals or experienced contractors can help you determine the ideal thickness based on your system's specifications.

AC Copper Pipe Sleeve

An AC Copper Pipe Sleeve serves as a protective covering for copper pipes, offering insulation against temperature variations and preventing condensation buildup. By incorporating an AC copper pipe sleeve into your installation, you enhance energy efficiency by reducing heat loss or gain along the pipeline. Properly insulating your copper pipes with sleeves contributes to maintaining consistent temperatures within your air conditioning system.

HVAC professionals emphasize the importance of selecting the right AC Copper Pipe Thickness and utilizing quality materials like an AC copper pipe sleeve to optimize performance and longevity. By considering factors such as refrigerant type, system pressure, and insulation methods, you can design a reliable HVAC system tailored to meet your cooling needs effectively.

Installation Considerations

When it comes to Proper Installation Techniques for your air conditioning system, attention to detail is paramount. Ensuring precise measurements and secure connections can significantly impact the overall performance and longevity of your HVAC setup. Here are some essential steps to follow when installing copper pipes for your air conditioning system:

Begin by carefully planning the layout of your copper pipes to optimize efficiency and minimize bends or kinks that could restrict airflow. Precision in positioning the pipes ensures smooth operation and even distribution of cool air throughout the space.

Next, use high-quality tools and equipment to cut and shape the copper pipes accurately. Accuracy in cutting and bending the pipes is crucial for seamless connections and preventing leaks that could compromise system efficiency.

Secure the copper pipes firmly in place using appropriate fasteners or brackets to prevent movement or vibrations that may cause damage over time. Stability in mounting the pipes safeguards against potential wear and tear, ensuring long-lasting performance.

Pay close attention to sealing joints effectively with reliable methods such as soldering or brazing to maintain airtight connections. Airtightness in joints prevents refrigerant leaks and preserves system integrity for optimal cooling capacity.

AC Co Efficiency

The AC Co Efficiency, also known as Air Conditioning Coefficient of Performance, measures the efficiency of an air conditioning system by evaluating its cooling output relative to energy consumption. A higher AC Co Efficiency indicates a more energy-efficient system that provides greater cooling capacity while consuming less power.

To enhance your AC Co Efficiency, consider implementing these strategies:

Regular maintenance: Schedule routine inspections and maintenance checks to ensure all components are functioning correctly, optimizing system performance.

Upgrading insulation: Improve insulation around ductwork and copper pipes to reduce heat loss or gain, enhancing overall energy efficiency.

Investing in programmable thermostats: Utilize programmable thermostats to regulate temperature settings based on occupancy patterns, reducing energy waste.

Proper sizing: Ensure your air conditioning system is appropriately sized for your space to prevent unnecessary energy consumption due to oversized units.

By focusing on improving your AC Co Efficiency through proper maintenance and strategic upgrades, you can achieve a more sustainable and cost-effective cooling solution for your property.

Maintenance Tips

Maintaining your air conditioning system is essential for prolonging its lifespan and maximizing performance. Follow these maintenance tips to keep your HVAC setup running smoothly:

Clean or replace filters regularly: Clogged filters restrict airflow, reducing efficiency. Ensure filters are clean or replace them as needed.

Check for leaks: Inspect copper pipes for any signs of leakage or corrosion that could impact system functionality.

Monitor refrigerant levels: Low refrigerant levels can affect cooling capacity; schedule professional inspections to maintain optimal levels.

Clear debris around outdoor units: Keep outdoor condenser units free from debris like leaves or dirt that can obstruct airflow.

Schedule professional tune-ups: Regular servicing by HVAC professionals can identify potential issues early on, preventing costly repairs down the line.

By adhering to these maintenance tips diligently, you can extend the longevity of your air conditioning system while enjoying consistent comfort within your living or working environment.

Matching the thickness of copper pipe walls to specific application needs is crucial for optimal performance.

The choice of copper pipe type should align with system requirements, local building codes, and industry standards.

Consulting with professionals is advisable to determine the most suitable copper pipe type for a particular application.

See Also

Benefits of Opting for Copper Tubing in Air Conditioning

Key Factors in Selecting the Proper Copper Pipe Size

Comprehensive Manual for Choosing Copper Pipe Coils