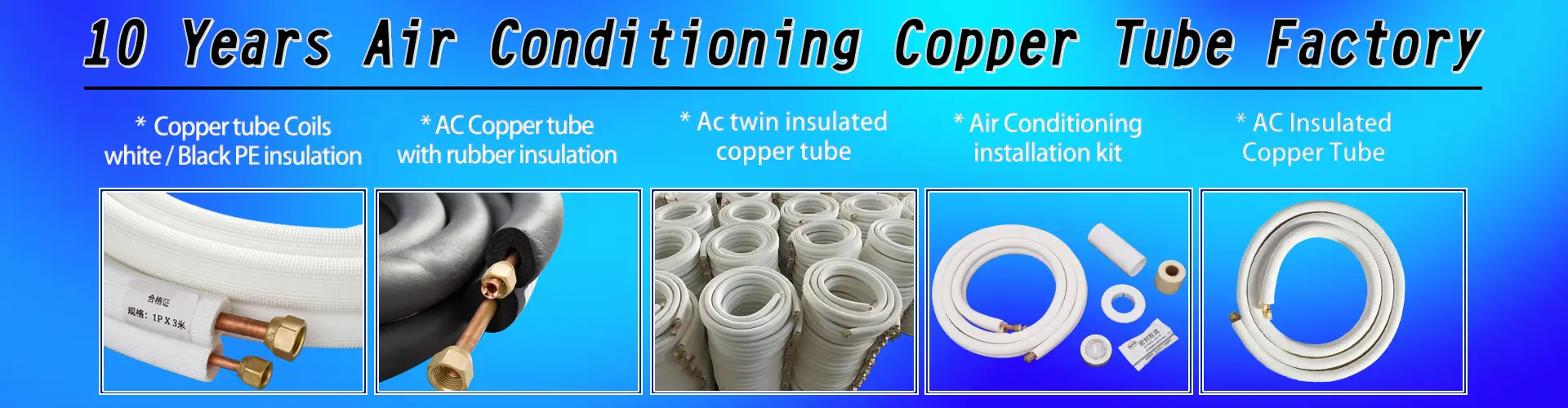

5 Ways Customized Pure Copper Tubes Revolutionize Air Conditioner Designs

The significance of air conditioner design cannot be overstated in today's HVAC industry. Introducing customized on demand pure copper tubes, a game-changer in enhancing air conditioner efficiency. These pure copper tubes are at the forefront of innovation, reshaping designs in five crucial ways. Additionally, the use of thickened pure pipe ensures durability and optimal performance in various air conditioning systems.

Enhanced Durability

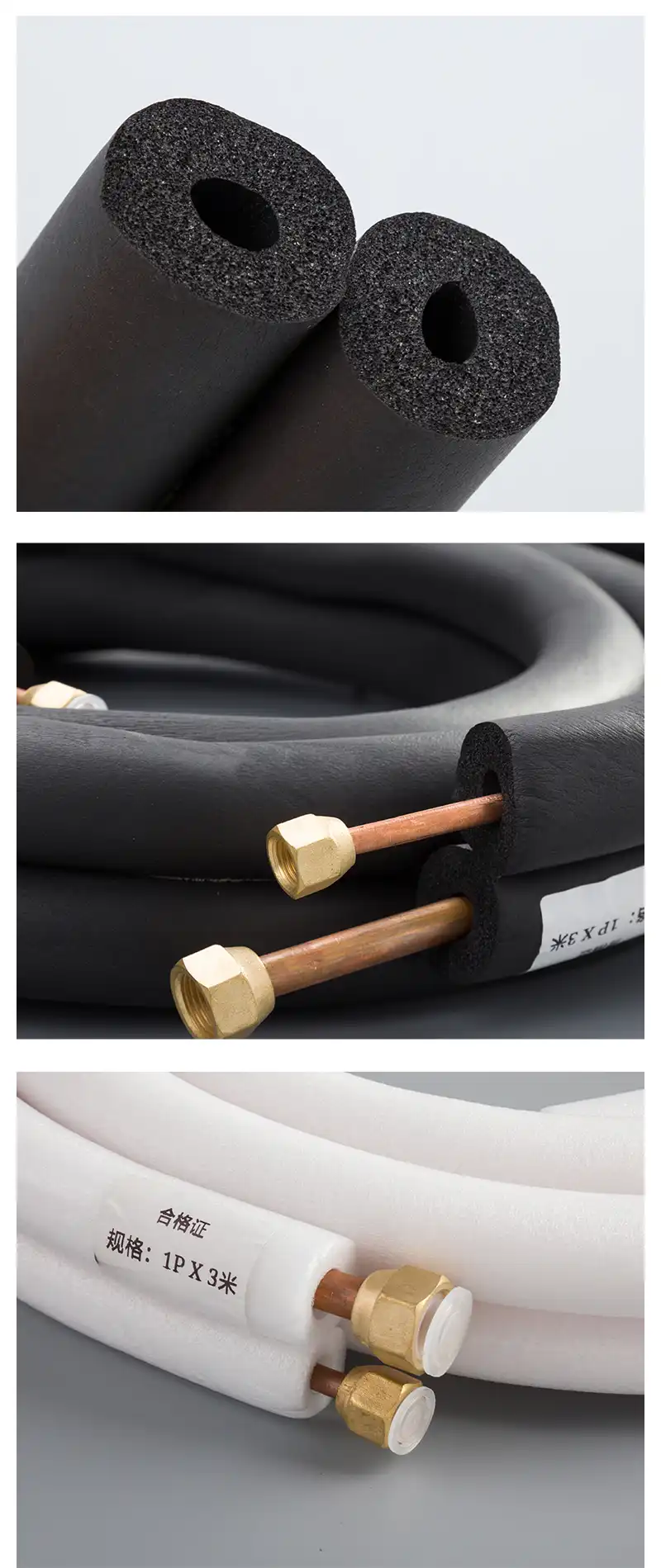

Anti-Cracking Features

To ensure the longevity and robustness of air conditioner designs, thickened pure pipe plays a pivotal role in enhancing durability. The incorporation of this feature fortifies the structural integrity of the system, mitigating the risk of potential leaks or damages over time. By reinforcing the composition with increased thickness, these pure pipes exhibit exceptional resistance to external pressures and environmental factors, thereby extending the lifespan of the air conditioning unit.

Long-Term Performance

In addition to its anti-cracking properties, thickened pure pipe offers unparalleled corrosion resistance, further bolstering the long-term performance of air conditioners. This resistance to corrosion ensures that the copper tubes maintain their efficiency and functionality even in challenging environments or prolonged usage scenarios. The enhanced durability provided by these features not only guarantees a reliable operation but also minimizes maintenance requirements, making them a cost-effective solution for modern HVAC systems.

Improved Efficiency

Seamless Connections

Precision Flaring Ends

In the realm of air conditioner design, achieving seamless connections is paramount for optimal performance. The integration of precision flaring ends in customized on-demand pure copper tubes ensures airtight seals without any irregularities. This meticulous engineering process guarantees a perfect fit between components, eliminating any potential leaks or inefficiencies in the system. By prioritizing precision in the connection points, air conditioners can operate at peak efficiency levels, maximizing their cooling capabilities.

The use of precision flaring ends not only enhances the overall functionality of air conditioners but also simplifies maintenance procedures. With secure and seamless connections, technicians can easily access different parts of the system for inspections or repairs without disrupting the entire setup. This streamlined approach to maintenance reduces downtime and minimizes service costs, making it a practical solution for both residential and commercial air conditioning units.

Optimal Heat Transfer

High Thermal Conductivity

Optimizing heat transfer is a fundamental aspect of air conditioner efficiency, and customized on-demand pure copper tubes excel in this domain. Their high thermal conductivity properties facilitate rapid heat exchange processes within the system, ensuring quick and efficient cooling cycles. By efficiently transferring heat away from the living space, these copper tubes contribute to energy savings and enhanced comfort levels for users.

The utilization of high thermal conductivity materials like pure copper further underscores the commitment to sustainable HVAC solutions. Copper's ability to conduct heat effectively reduces energy consumption during operation, aligning with modern trends towards eco-friendly technologies. As a result, air conditioners equipped with high thermal conductivity copper tubes not only deliver superior performance but also promote environmental responsibility in HVAC applications.

By leveraging scientific research findings that highlight copper's advantages in performance and efficiency compared to other materials, manufacturers can continue to innovate and elevate air conditioner designs to new heights. The emphasis on seamless connections and optimal heat transfer through precision engineering and high thermal conductivity materials sets a new standard for excellence in modern air conditioning systems.

Customization Flexibility

Tailored Dimensions

In the realm of air conditioner designs, customized on-demand pure copper tubes offer unparalleled flexibility through tailored dimensions. Manufacturers can precisely adjust the length, thickness, and diameter of these tubes to meet specific requirements, ensuring a perfect fit for diverse cooling systems. This customization capability allows for seamless integration within various air conditioner models, optimizing performance and efficiency.

Customized on Demand

The ability to request customized on-demand pure copper tubes plays a pivotal role in enhancing design adaptability. By tailoring the dimensions based on unique specifications, HVAC professionals can address specific cooling needs with precision and accuracy. This bespoke approach ensures that each component aligns seamlessly with the overall system, promoting optimal functionality and reliability.

Versatility in Applications

When considering different air conditioner models, the versatility of customized on-demand pure copper tubes shines through. These adaptable components are suitable for a wide range of applications, including split systems, window units, and central air conditioning setups. Their compatibility with various models underscores their universal appeal and essential role in modern HVAC systems.

Different Air Conditioner Models

The adaptability of customized on-demand pure copper tubes across different air conditioner models highlights their versatility and practicality in diverse settings. Whether used in residential or commercial units, these customizable tubes provide consistent performance and efficient heat transfer capabilities. Their widespread application underscores their significance in revolutionizing air conditioner designs for optimal functionality.

SPX Cooling Tech highlights that copper offers nearly 7X higher thermal conductivity than steel, leading to enhanced equipment efficiency and reduced power consumption. This superior conductivity allows for compact designs without compromising performance, resulting in cost-effective solutions for HVAC systems. According to Nigel Cotton, coils made from MicroGroove copper tubes are set to drive innovation in refrigeration and air-conditioning products. The continuous advancements in copper technology underscore its pivotal role in shaping the future of HVAC systems, ensuring sustainable and efficient cooling solutions for years to come.

CN

CN English

English